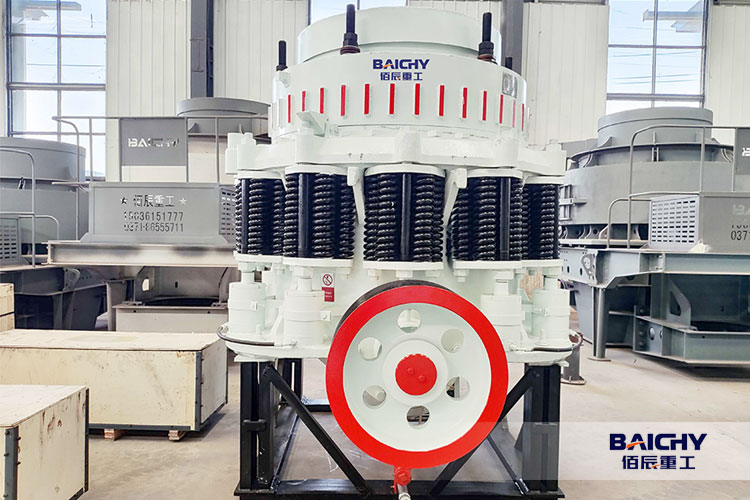

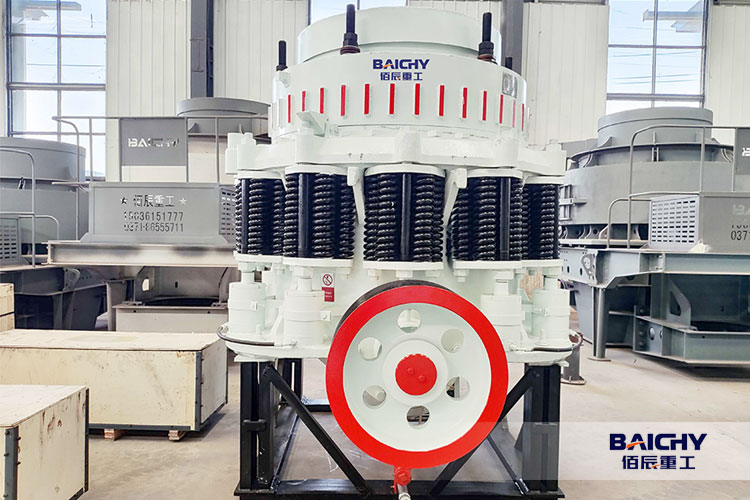

Symons cone crusher is a high-performance stone crusher based on the laminated crushing principle and the concept of more crushing and less grinding. The diameter of symons cone crusher CS110 is 4 ft ( 1200mm). So it is also called 4’ symons cone crusher. Compared with PY series spring cone crusher, it has the characteristics of reliable structure, high production efficiency, convenient adjustment and economical use.

Cone crusher CS110 technical spec

| Model |

Chamber

type

|

Cone dia.

(mm)

|

Adjusting Range of

Discharge Opening(mm)

|

Max feeding

size (mm)

|

Capacity

(t/h) |

Motor

(kw) |

Overall size

(mm) |

| CS110 |

C |

1200(4') |

19-50 |

180 |

110-250 |

110 |

2821×1974×2651 |

| CS110 |

M |

1200(4') |

13-38 |

130 |

80-180 |

110 |

2821×1974×2651 |

| CS110 |

F |

1200(4') |

9-31 |

90 |

63-140 |

110 |

2821×1974×2651 |

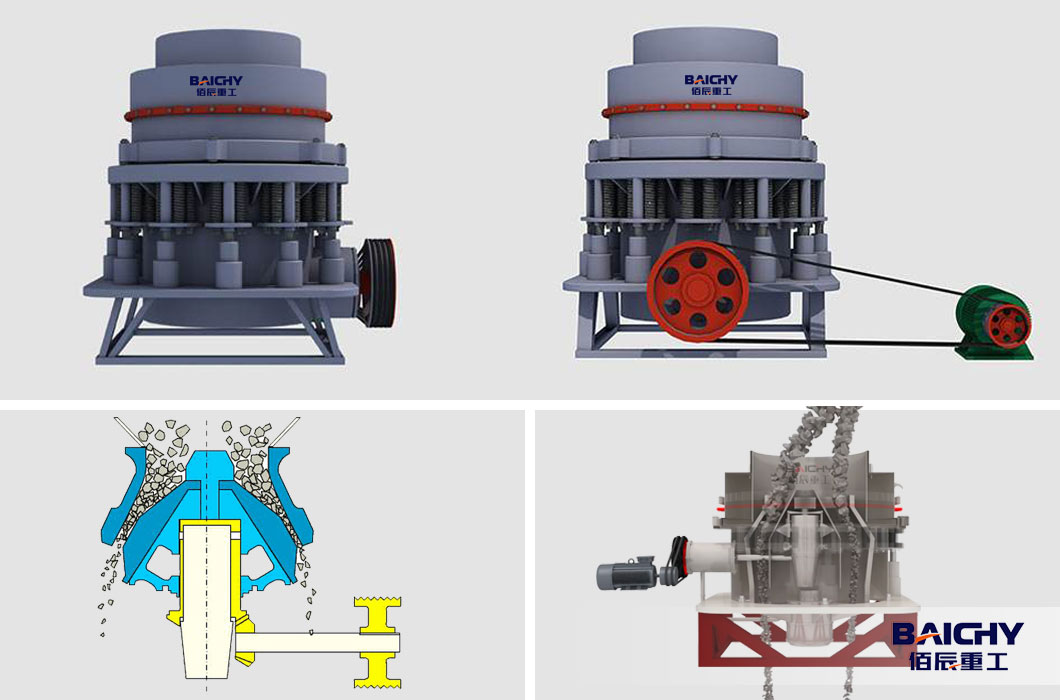

How does cone crusher work?

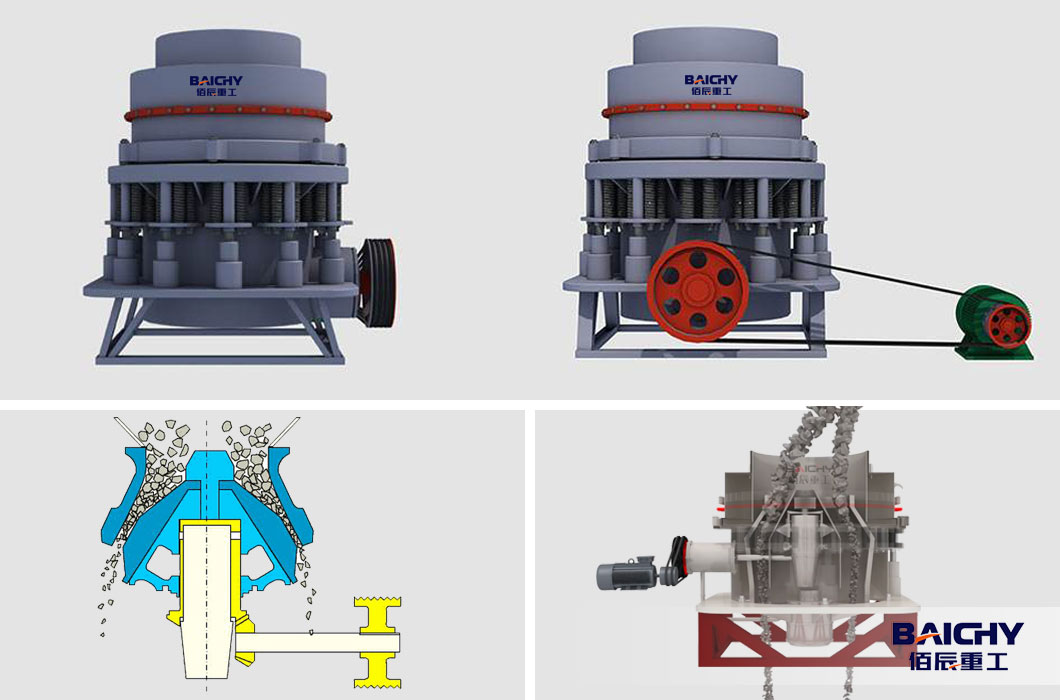

When Symons 4ft std cone crusher working, the motor drives the eccentric sleeve to rotate through the V-belt, large pulley, transmission shaft, small bevel gear, and large bevel gear. The axis line of the crushing cone rotates and moves under the eccentric sleeve’s force, causing the surface of the crushing wall to rotate. Sometimes it approaches and sometimes leaves the rolling mortar wall, so that the material is again cone-shaped in the annular crushing cavity composed of the moving cone, and is continuously crushed by extrusion, impact and bending. After many times of extrusion, impact and bending, the material is crushed to required particle size and discharged through the cone crusher lower part.

Symons cone crusher CS100 Features

1.Good stability

The safety protection measure is a spring group installed around the frame as a safety device. When non-crushed objects enter the cone crushing cavity, the support ring and adjustment ring are forced to lift upwards to compress the spring, thereby increasing the distance between the movable cone and the fixed cone, increasing the size of the ore discharge port. Eject non-crushing objects to avoid damage to the machine.

2.Good particle size composition of the product

The principle of cone crusher lamination and crushing is adopted to significantly increase the proportion of cubes in the product, reduce the number of needle-shaped stones, and make the particle size more uniform.

3.Convenient cavity cleaning

If cone crushing machine stops under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing downtime.

4.Easy maintenance and operation

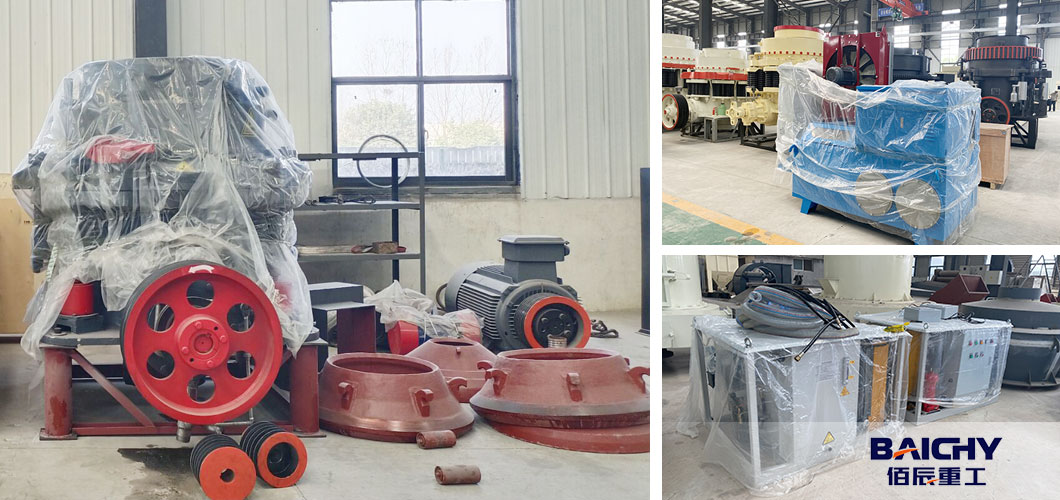

All parts can be disassembled from the top or side, so that both the fixed cone and the moving cone assembly can be easily disassembled. Bronze sliding bearings can maintain excellent load-bearing performance in high impact, vibration and crushing environments, and are more economical and easier to maintain than rolling bearings.

5.Split lubrication

The independent thin oil lubrication system with multi-point control can ensure double protection of bearing lubrication of this model, and can realize automatic safety protection of the entire symons cone crusher machine.

6.Wide application

CS series high-efficiency spring cone crusher is characterized by maximizing the performance of the crusher to be suitable for various crushing processes: from extra coarse crushing to fine crushing, from fixed crushing plant to mobile crushing stations.

Symons cone crusher CS110 application

1.Cone crusher for granite crushing plant in Zimbabwe

Granite is a very strong and durable natural stone in Africa , but it can still crack under certain circumstances. To crush granite efficiently, the lamination type crushing machine is good choice. We setup a complete granite crushing line in Zimbabwe. The whole crushing plant consists of feeding machine, crushing machine, screening machine and conveying system.

a.The vibrating feeder feeds the raw material into the jaw crusher steadily and evenly for primary crushing.

b.All the crushed material came out from jaw crusher will be transported to the cone crusher for the secondary crushing.

c.After that, all the material will be transported to a vibrating screen and the material will be separated into different required sizes.

2.Mobile cone crushing and screening plant

Mobile cone crusher is a proven high capacity and aggressive machine for the surface ore mining and aggregate industries. It is the ultimate mobile machine for providing large reduction ratios and an excellent cubical shaped end product. Combined with mobile jaw crusher, the whole crushing plant footprint is smaller and compact. After materials is classified by the multi-layer vibrating screen, large size material from first layer could be fed into cone crusher directly without belt conveyor. Other materials are final aggregates with good shape.

People Also Frequently Asked For - FAQ

Is granite hard to crush?

To crush granite, you need to use a crusher machine that can handle the tough and abrasive nature of granite stones. A jaw crusher or cone crusher can be used as the primary crushing machine. A impact crusher may be used as a secondary crushing machine. The crushed granite can be screened to get the desired size.

Is cone crusher a primary crusher?

Cone Crushers are compression-type crushers that are typically found in secondary crushing stages but can be used as the primary crusher in certain applications. They handle medium hard to very hard, abrasive materials that can be dry or wet but not sticky.

What is the maintenance of cone crushers?

Check the oil level and quality: The oil level should be checked daily, and if it's low, add the recommended oil.

Inspect the components: Inspect the components, such as the liners, mantle, and concave, for wear and damage.

2025-04-14

2025-04-14

86-15093113821

86-15093113821

86-15093113821

86-15093113821