Symons cone crusher 4 1/4' and CS160 are same model. It adopts the laminated crushing principle to form a protective layer for the material layer. It has the characteristics of reliable structure, high crushing efficiency, convenient adjustment, and economical use. CS series cone crusher has been widely used in metal and non-metal mines, cement plants, construction, metallurgy, transportation, sand and gravel aggregate production and other industries, especially suitable for iron ore, gold ore, non-ferrous metal ore, granite, basalt, calcite, etc. Crushing of hard and medium-hard ores and rocks such as greenstone and quartzite.

Technical Parameters:

| Model |

Cavity

type

|

Cone

dia(mm)

|

Discharge Opening

range(mm)

|

Max feeding size

(mm)

|

Capacity

(t/h) |

Motor

(kw) |

Overall size

(mm) |

| CS160 |

C |

1295 (4 1/4') |

19-51 |

205 |

172-349 |

160 |

2983×1866×3156 |

| CS160 |

M |

1295 (4 1/4') |

16-38 |

178 |

132-253 |

160 |

2983×1866×3156 |

| CS160 |

F |

1295 (4 1/4') |

13-31 |

115 |

109-181 |

160 |

2983×1866×3156 |

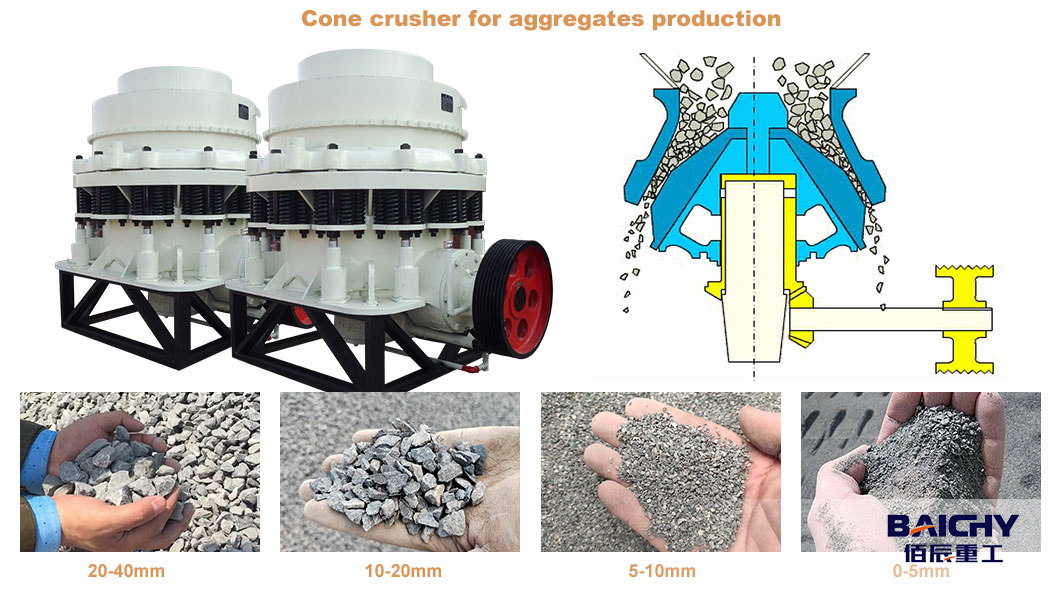

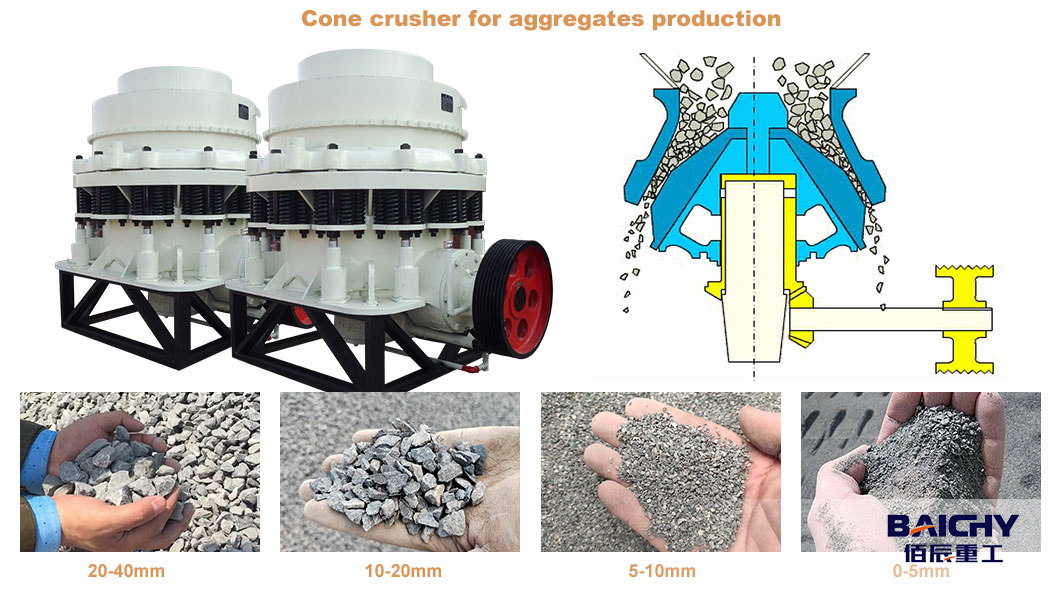

The output size of cs160 cone crusher is related to the crushing cavity type. The fine crushing cavity type has small feed and discharge sizes and low output. The medium crushing cavity type is in the middle. The coarse crushing cavity type has large feed and discharge sizes and output. It's also relatively large.

Cone Crusher Features:

1. Multiple crushing cavity types: The cavity types of CS 160 cone crushers are divided into three different design methods. Users can choose according to the site conditions. It has high crushing efficiency, uniform product particle size, good particle shape, uniform wear of the rolling mortar wall and long service life. crushing cavity type.

2. Dry oil seal and dustproof: CS160 cone crusher adopts dustproof sealing structure, which has reliable sealing effect and effectively extends the lubricating oil replacement cycle and the service life of parts.

3. Support large crushing force: The key parts of CS series cone crusher are made of special materials. The distance between the crushing cone and the rolling mortar wall is up to 100% in each stroke, which not only allows more materials to enter the crushing cavity, but also forms a larger discharge volume, which accelerates the speed of materials passing through the crushing cavity.

4. High output: Compared with other models, the CS series cone crusher has long crushing wall, large stroke and large crushing force. It can effectively crush the materials in the crushing cavity and crush more materials per stroke.

5. Low maintenance cost for daily operation: reasonable parts selection and structural design, long service life, large crushing force wall, reducing the load on sliding bearings, gears and frames, uniform crushing force, reducing cyclic load, hydraulic cleaning The cavity system is easy to operate, reduces downtime, has low power consumption and reasonable distribution.

Cone Crusher Working Principle

Cone crusher consists of a moving cone and a fixed cone forming a crushing cavity. The movable cone is press-fitted on the main shaft (hard shaft), and one end of the main shaft is inserted into the tapered hole of the eccentric sleeve. The tapered hole of the eccentric sleeve is equipped with a bronze bushing or nylon bushing. When the transmission gear drives the eccentric sleeve to rotate, the main shaft deep inside the eccentric sleeve drives the movable cone to rotate and swing, causing the conical surface of the movable cone and the fixed cone to separate and close intermittently, resulting in crushing and discharge of ore.

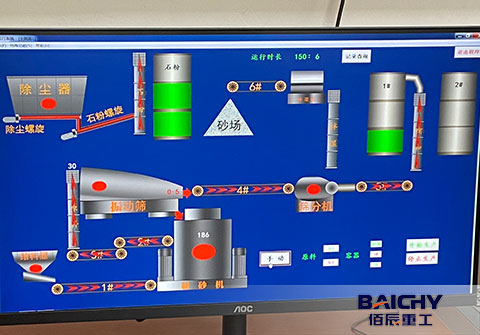

Application: Cone crusher CS160 for Granite Crusher Plant 200tph

Material: granite

Input Size: 0-630mm

Output Sizes: 0-5mm, 5-15mm, 15-31.5mm

It is configured with hopper, vibrating feeder ZSW1149, primary jaw crusher PE-750X1060, cone crusher CS160, vibrating screen 2YK2160, VSI 1142, 3-layer vibrating screen 3YK2160, and belt conveyors.

Processing:

1. The truck unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper. The vibrating feeder feeds the stones evenly to the primary jaw crusher;

2. The crushed output materials from the primary jaw crusher will be transported to the secondary cone crusher.

3. The crushed output materials from the secondary cone crusher will be transported to the two-layer vibrating screen;

4. After screening by the two-layer vibrating screen, will get 0-5mm, 5-35mm, +35mm materials, 0-5mm materials will be transported out by a belt conveyor to stockpile, 5-35mm materials will be transported to VSI Crusher, +35 materials will be transported back to cone crusher for re-crushing.

5. 5-35mm materials will be crushed and shaped by VSI crusher, the output materials will be transported to the second vibrating screen;

6. After the screening, will get 0-5mm, 5-15mm, 15-31.5mm materials, the +31.5mm materials will be transported back to VSI crusher.

People Also Frequently Asked For - FAQ

What is the difference between cone crusher and VSI?

In general, impact crushers both vertical shaft (VSI) and horizontal shaft (HSI), the main difference from the cone crusher is the type of crushing force. The impact crusher crush by material impacting another object.

Which oil is used in cone crusher?

32 hydraulic oil is used for the hydraulic oil tank of multiple cylinder cone crusher and 150 gear oil is used for lubricating oil tank. Therefore, the choice of oil for cone crusher is directly related to the equipment. In terms of the brand, Mobil and Shell can be selected.

Where is cone crusher used?

Cone crushers are popular rock crushing machines in aggregates production, mining operations, and recycling applications. They are normally used in secondary, tertiary, and quaternary crushing stages.

2025-04-02

2025-04-02

86-15093113821

86-15093113821

86-15093113821

86-15093113821