Manufactured sand is an important material for infrastructure projects. How to choose appropriate green and environmentally friendly manufactured sand production equipment is something that needs to be considered when investing in a manufactured sand production line. We take the semi-dry sand making process as an example to describe the key points of equipment selection and process design in the manufactured sand production line for your reference.

Main sand making equipment selection

1. Primary coarse crushing equipment

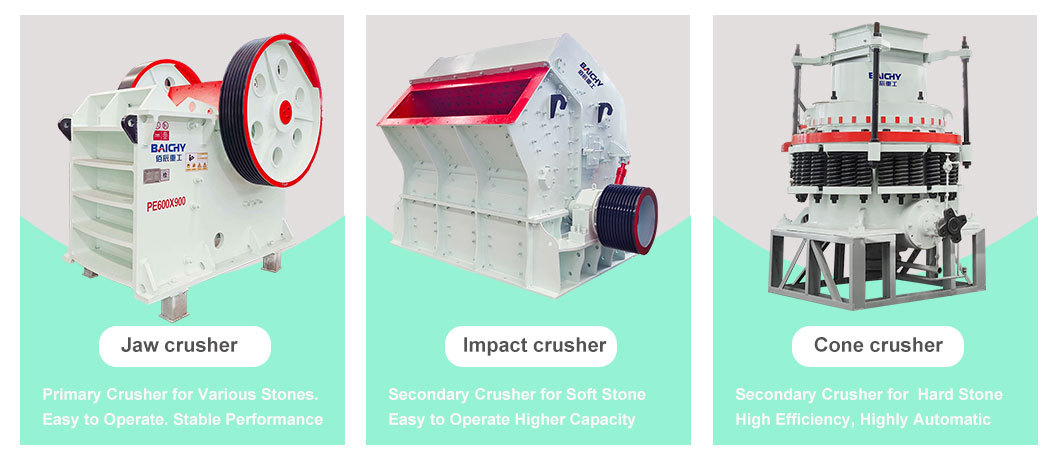

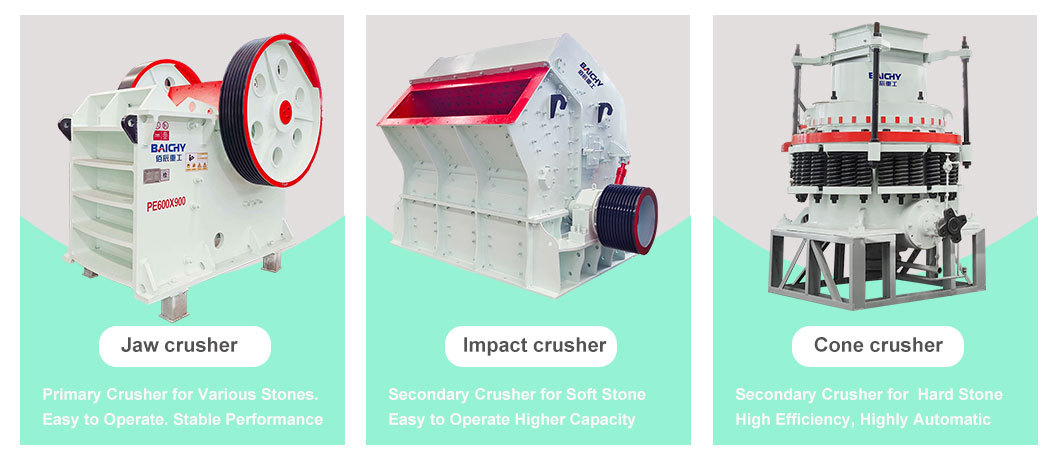

Coarse crushing equipment used for aggregate production is generally gyratory crusher, jaw crusher and impact crusher. If the production capacity requirements are high, greater than 1000t/h, it is recommended to use rotary crusher.

2. Secondary medium and fine crushing equipment

Medium and fine crushing equipment generally include cone crushers and impact crushers, and sand making machines are often used for the last stage of sand making and shaping.

The cone crusher is mainly suitable for crushing rocks with high hardness and high abrasiveness index, and the product has less powdery material.

The impact crusher is mainly suitable for crushing rocks with medium or low hardness and abrasiveness index, and the products contain more powdery materials. If the demand for powdery materials is poor, a standard cone crusher can be used for medium crushing, and a short-head cone crusher can be used for fine crushing.

3. Screening and washing equipment

Stone screening equipment generally uses linear vibrating screens or circular vibrating screens.

The linear vibrating screen has a small processing capacity and is suitable for small particle size screening and small output production. It can be used for water filtration of water-containing materials.

The circular vibrating screen has high screening efficiency and large processing capacity, and is suitable for large particle size screening and large-scale production.

When the circular vibrating screen is equipped with a pressure water spray system, it can be used as a stone washing equipment. With the help of hydraulic flushing, the stones roll and vibrate on the screen surface, making it easier to wash away the fine mud adhering to the surface.

For mud powder and stone powder in 0-4.75mm products, you can generally choose a spiral sand washing machine or bucket wheel sand washing machine to obtain manufactured sand.

4. Waste water and mud treatment equipment

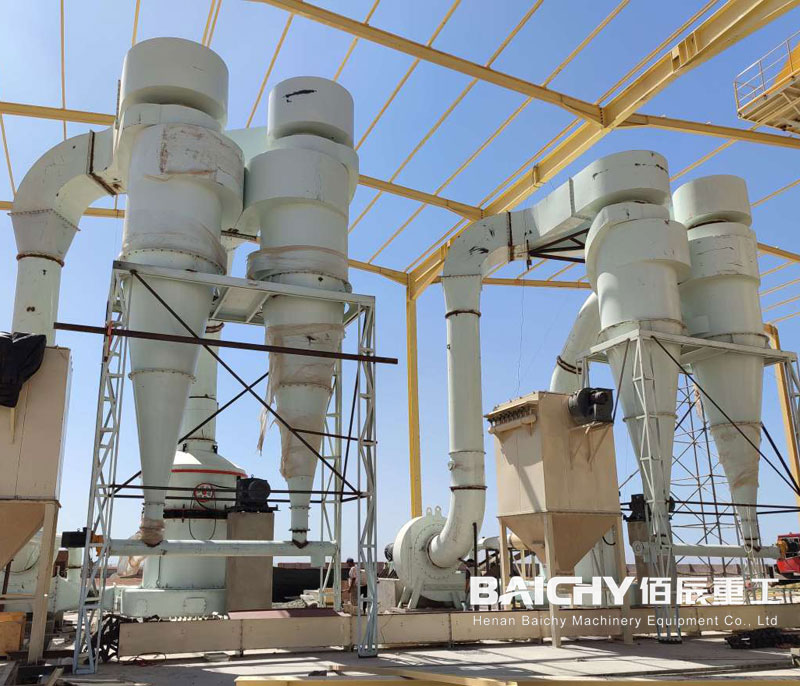

The muddy wastewater after washing sand and gravel aggregates needs to be treated to achieve zero discharge of wastewater from the production line. After inspecting the wastewater treatment equipment, a system consisting of a cyclone group, a concentrator and a filter press was selected to treat wastewater and mud. This can avoid the direct discharge of mud-containing wastewater into the sedimentation tank, which would cause a large area and The disadvantage of settling tanks is that they are difficult to clean.

Key points of sand production line design

1. Set up an intermediate material storage shed.

The intermediate material stacking shed can adjust the overall system production capacity of the aggregate production line. When the rough crushing section is overhauled, the downstream aggregate production section will not stop production. When mining can only be produced in day shifts, the downstream aggregate production section can still be produced in two shifts, and the number of equipment can be reduced. Adjusting system production capacity through production shifts reduces investment and gives full play to the advantages of each system equipment.

2. Make full use of the terrain height difference.

Any production line design that can minimize construction investment and operating costs is a very good design. Adapting measures to local conditions and making full use of terrain height differences for process layout can not only reduce civil construction investment and equipment investment, but also reduce production and operation costs.

3. Design pre-screening before medium and fine crushing.

If the raw material contains clay, it is generally difficult to remove it through screening. The design of pre-screening can not only screen out soil-containing waste materials smaller than a certain particle size when the soil content of the raw materials is high, but also prevent aggregates smaller than the required particle size after coarse crushing from going through medium and fine crushing. , thereby increasing system output and reducing the production of powdery materials.

4. The finished screen is sprayed and washed with single-layer vibrating screen.

The purpose of spraying the first-level vibrating screen of the semi-dry sand and gravel aggregate production line is to remove part of the soil and wet the materials that are difficult to clean as soon as possible so that the mud-containing materials can be soaked in advance. The second and third-level finished vibrating screens are designed as single layers. The purpose of spray water washing is to make each material product have the opportunity to directly contact with clean water, thereby improving the cleanliness of the aggregate products.

5. Sand and gravel washing system.

For mud-containing wastewater, due to the large amount of mud and sand and large particle size, it is not suitable to use a slurry pump to transport it. It can only flow to the sand washing machine through the water tank. In this link, the distance of wastewater flow and the angle of the sink should be fully considered. The sand washing machine workshop should be arranged on a lower stage than the vibrating screen workshop as much as possible. The sink should be made into a U-shaped groove to reduce friction. A water filter screen should be installed at the discharge of the sand washing machine and the discharge of the cyclone group to avoid excessive moisture content in the materials entering the finished product yard and affecting product sales.

6. Waste cement material treatment system.

When the wastewater containing mud powder after sand washing enters the concentration tank, the location of the dosing point must be reasonable and the amount of dosing must be appropriate to improve the effect of the concentrator system. A buffer mixing tank should be set up in front of the filter press to meet the requirements of continuous operation of the slurry pump after the thickener and intermittent operation of the filter press. The selection of filter press capacity should fully consider the time required for each operation and the moisture content requirements of the mud cake.

Product storage and shipping.

The design key point of this link is that in addition to suitable discharging equipment, at least 1 to 2 measuring scales should be installed under each pile to adjust the reasonable gradation of sand and gravel to meet customer needs for different grade sand and gravel aggregates. .

7. Environmental protection.

a) Dust prevention and dust collection measures

The design generally adopts the policy of giving priority to prevention and combining prevention and control. Minimize dust points in all process steps before medium and fine crushing, and use conveying and feeding equipment with good sealing performance. When designing the material pipe connected to the equipment, pay attention to the shape and angle of the material pipe, and try to reduce the gap as much as possible. High-efficiency dust collectors with high dust collection efficiency and reliable technology are used at all dust emission points to ensure that the dust emission concentration is lower than the national standard.

The intermediate materials and earth-containing waste materials are stored in closed sheds and spray dust removal to reduce the impact of dust on the surrounding environment.

b) Noise control

To control noise, try to select low-noise equipment in terms of equipment selection, and arrange the noise source equipment in a closed factory building, with greening outside the workshop to block the spread of noise.

C)Wastewater treatment and mud discharge

The wastewater is mainly domestic wastewater and sand washing wastewater.

After pretreatment, domestic wastewater and other wastewater are collected into the factory wastewater treatment station for treatment. After reaching the standard, it can be reused as water for the production line.

The wastewater generated by screening and washing is treated by the sand and gravel washing and waste cement material treatment systems and then recycled as production water. The mud cake after sludge treatment and the waste soil produced by pre-screening are used as mine reclamation cushion to achieve zero discharge of waste water and mud.

This article mainly focuses on the equipment selection and design points of the semi-dry sand production line. In actual production, the sand and gravel aggregate production processes and equipment configurations are diverse. The specific design should be based on local conditions and tailored according to production requirements. Welcome to contact us for professional solution for manufactured sand making plant.

People Also Frequently Asked For-FAQ

What is the difference between crushed sand and manufactured sand?

The terminology is just different. Manufactured sand IS crushed sand. Since sand has many functions, the type of rock used, and the gradation are adjusted to what is available, and what characteristics are required.

How does a sand crusher work?

A crusher usually consists of a hopper, a feeder, and a crushing mechanism. The hopper is used to contain the rocks that enter into the crusher. The feeder pushes the rocks into the crushing mechanism where it is then broken down into smaller pieces of sand.

How do you manufacture sand?

Sand can also be produced mechanically. The raw material for manufactured sand usually comes from bedrock and is produced in the same way as sand is formed naturally: The rocks are crushed and grinded into ever smaller pieces

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821