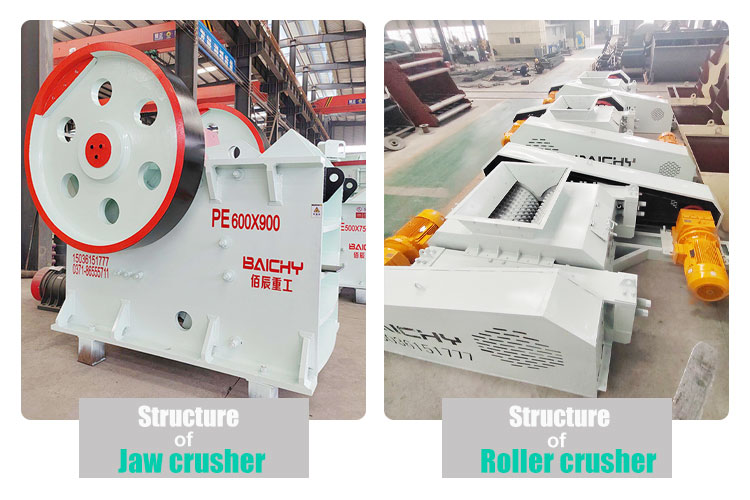

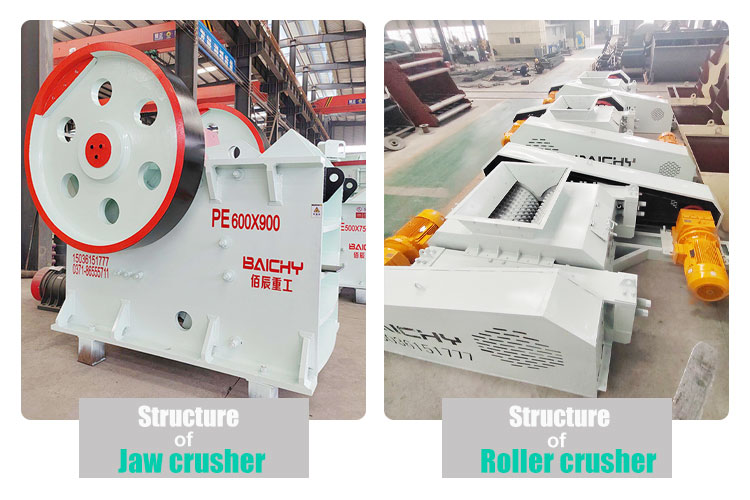

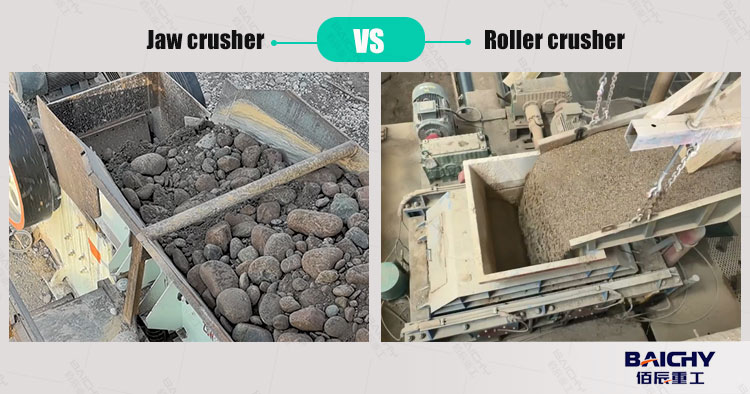

Both jaw crusher and roll crusher are simple structure and crush hard material by extrusion force. Jaw crushers are mainly used for coarse crushing and medium crushing processes, and roller crushers are fine crushing machines. What is the difference between jaw crusher and double roller crusher? Let's move on to the following items to know about difference

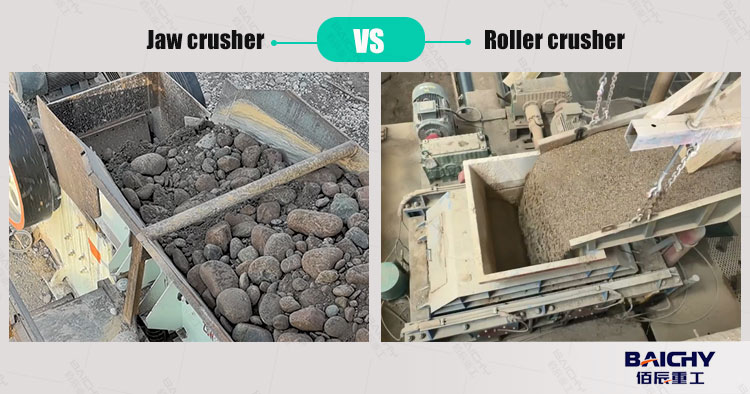

1. Applicable material

Jaw crusher is used for crushing hard, abrasive materials like rocks in primary crushing stages. It is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries for primary or secondary crushing of various ores and bulk materials whose compressive strength is less than 320Mpa.

Double roller crusher is more suitable for softer, less abrasive materials and can handle slightly wet or sticky feed, often used for secondary crushing applications where a more consistent particle size is neededmostly. It is used in cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines, etc., such as coal, coal gangue, coke, limestone , iron ore, quartz stone, sulfur ore, etc. The crushed material is usually brittle, the compressive strength is no more than 160Mpa, and the water content is no more than 6%, otherwise there will be particle bonding.

2.Material feeding size

Jaw crusher is large crushing ratio and high capacity. The feed inlet of the large jaw crusher is larger than 600MM, that of the medium-sized one is 300-600MM, and that of the small one is below 300MM.

Double roller crusher is suitable for medium and fine crushing of materials with a size less than 150mm. The finished product is uniform in shape. Low power consumption, low noise, sensitive overload protection.

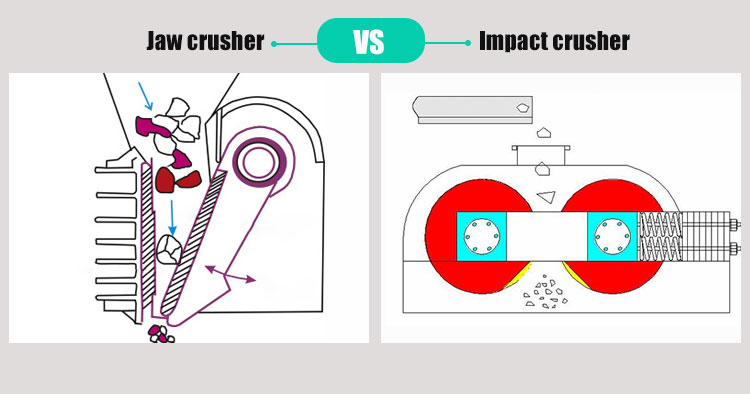

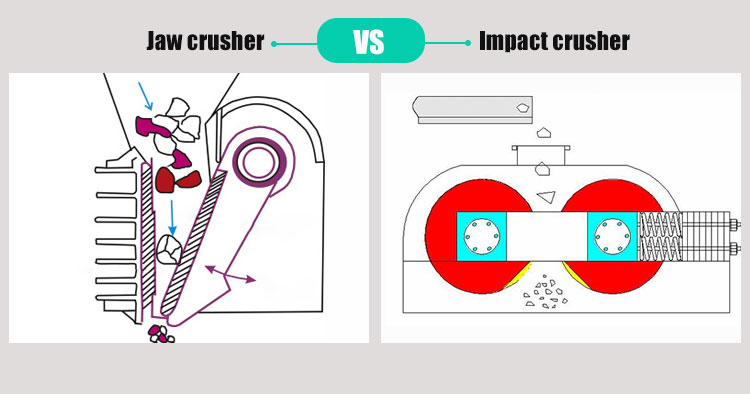

3.Working principle

Jaw crusher is composed of two jaw plates, the movable jaw and the fixed jaw. The material is crushed by extrusion using a compressive force between two jaw plates. When working, the motor drives the eccentric shaft to rotate through the pulley, so that the movable jaw approaches and leaves the fixed jaw periodically, so as to exert multiple forces such as extrusion, rubbing, and grinding on the material, and the crushed material gradually falls until it is discharged from the discharge port.

Roller crushers are a compression-type reduction crusher with two drums rotating about a shaft. It utilizes the compression between two rotating cylinders to break material down.The gap between the drums is adjustable. The particles are drawn into the crushing chamber by the rotating motions of the rolls and a friction angle is formed between the particles and the rolls. The stone fractures from the compression forces presented by the rolls as they rotate. The crushed particles are then forced between the rotating surfaces into the smaller gap area. Roll crushers are mostly used in smaller scale production to crush ores that are not too abrasive. This type of rock crushing equipment gives a very fine product size distribution with very little dust production.

4.Maintenance and repair

In terms of maintenance and repair, jaw crushers are generally easier to maintain and repair than roller crushers. This is because the components of a jaw crusher are simpler and easier to access than those of a roller crusher. However, roller crushers are often more durable and can handle more wear and tear than jaw crushers, which can make them a better choice for certain applications.

5.Technical data

The technical data sheet of jaw crusher and roller crusher is big difference too.

Jaw crusher VS Roller crusher

|

Machine

|

Jaw crusher

|

Roller crusher

|

|

Model

|

PE series

|

2PG series

|

|

Feeding size

|

<1200mm

|

<150mm

|

|

Discharge size

|

<600mm

|

<50mm

|

|

Motor power

|

5.5-380kw

|

2*(5.5-90)kw

|

|

Capacity

|

5-1000tph

|

2-300tph

|

In conclusion, while both roller crushers and jaw crushers are used to break down materials, they work in different ways and are used for different applications. Jaw crushers are commonly used in the mining and construction industries to break down larger materials, while roller crushers are used to handle smaller and more delicate materials, such as coal and ore. The choice of crusher ultimately depends on the specific needs of the application, including the size and type of material being crushed, as well as other factors such as maintenance and repair requirements.

People Also Frequently Asked - FAQ:

1.What are the disadvantages of roll crushers?

The disadvantage of roll crushers is that, in order for reasonable reduction ratios to be achieved, very large rolls are required in relation to the size of the feed particles. They therefore have the highest capital cost of all crushers for a given throughput and reduction ratio.

2.What is a roll crusher used for?

Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries.

3.Which type of crusher is best?

Different types of crushers are optimal for distinct crushing needs. Subjected to type and hardness of materials, capacity, feeding size, finished granular size, construction site, the chosen crusher could be jaw crusher, impact crusher, cone crusher, roller crusher, hammer crusher, vsi sand crusher etc.

4.What is the efficiency of roll crusher?

The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%. Abstracted from this article: http://www.ijettjournal.org/

2025-04-14

2025-04-14

86-15093113821

86-15093113821

86-15093113821

86-15093113821