The 1200 cone crusher is named because crushing cone diameter is 1200mm. It is a medium-sized crusher and is mainly used for secondary crushing of ores and rocks with medium or above hardness. Cone crusher is one popular crushing equipment in rock crushing production plant. It is widely used in mining, cement, highways, construction, water conservancy, power plants and other fields. It can crush pebbles, basalt, limestone, sandstone, iron ore, copper Materials with hardness ≤350MPa such as minerals have good medium and fine crushing effects.

1. Cone crusher PYB1200 motor power

The motor power of cone crusher is one of the technical parameters that users use as a reference before purchasing. Some customers asked whether the motor power affects the processing capacity. The answer is yes. The greater the motor power, the greater the crushing force. The stronger the production capacity. Cone crusher PYB1200 motor power is 8P 110KW, which is a large and medium-sized motor, enough to meet the needs of actual production.

2.1200 cone crusher output

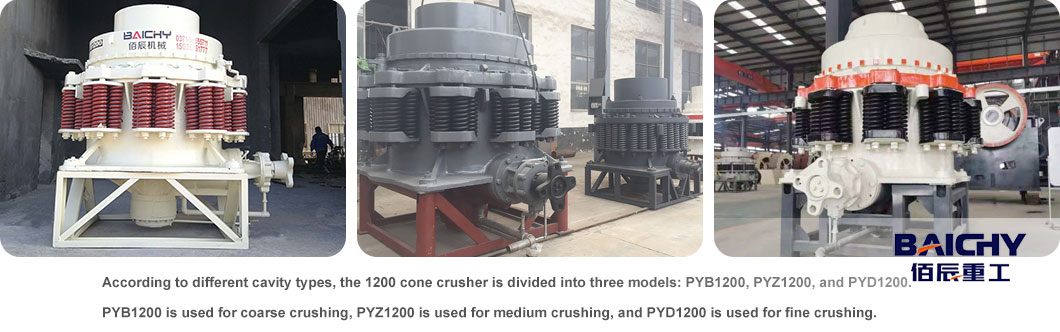

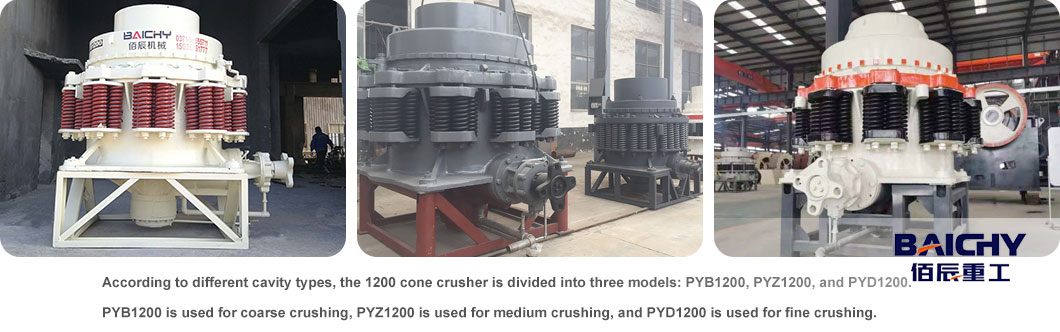

According to different cavity types, the 1200 cone crusher is divided into three models: PYB1200, PYZ1200, and PYD1200.

(1) The material size of PYB1200 is 145mm, the width of the discharge opening is 20-50mm, the total weight is 24.7t, and the processing capacity is 110-200t/h;

(2) The material size of PYZ1200 is 100mm, the width of the discharge opening is 8-25mm, the total weight is 25t, and the processing capacity is 50-150t/h;

(3) The material size of PYD1200 is 50mm, the width of the discharge opening is 3-15mm, the total weight is 25.3t, and the processing capacity is 18-105t/h.

It can be seen from the particle sizes of the finished products of the three models: PYB1200 is used for coarse crushing, PYZ1200 is used for medium crushing, and PYD1200 is used for fine crushing. Therefore, when purchasing a 1200 cone crusher, users must consider a variety of factors and purchase the appropriate equipment model.

3.Characteristics of 1200 cone crusher

1. High performance. Through cavity optimization design and the combination of reasonable speed and stroke.

2. Good stability. When non-broken objects such as iron blocks enter the body, the over-iron protection device will automatically release it and then reset automatically.

3. Using an automatic control system with a large diameter spindle, heavy-duty frame and independent thin oil lubrication system, the equipment is sturdy, durable and reliable in operation.

4. Widely used, cone crusher is suitable for various crushing processes, from coarse crushing to fine crushing, from fixed crushing production lines to mobile crushing stations, cone crusher PYB1200 is a good choice.

4. Cone crusher spare parts

Spring cone crusher is mainly composed of frame, transmission, hollow eccentric shaft, bowl bearing, crushing cone, adjustment device, adjustment sleeve, spring and hydraulic station for adjusting the ore discharge port. When the crusher is working, the motor drives the eccentric sleeve to rotate through the horizontal shaft and a pair of bevel gears. The axis line of the crushing cone makes a swing motion under the force of the eccentric sleeve, causing the surface of the crushing wall to sometimes approach and sometimes leave the rolling mortar wall. surface, so that the ore is continuously squeezed and bent in the crushing cavity to be crushed. The parts in contact with the material are the crushing wall and the rolling mortar wall, or called mantle and concave. Thay are commonly used wearing parts of the cone crusher. Our company can provide matching wearing parts of the cone crusher to ensure that the equipment can operate normally.

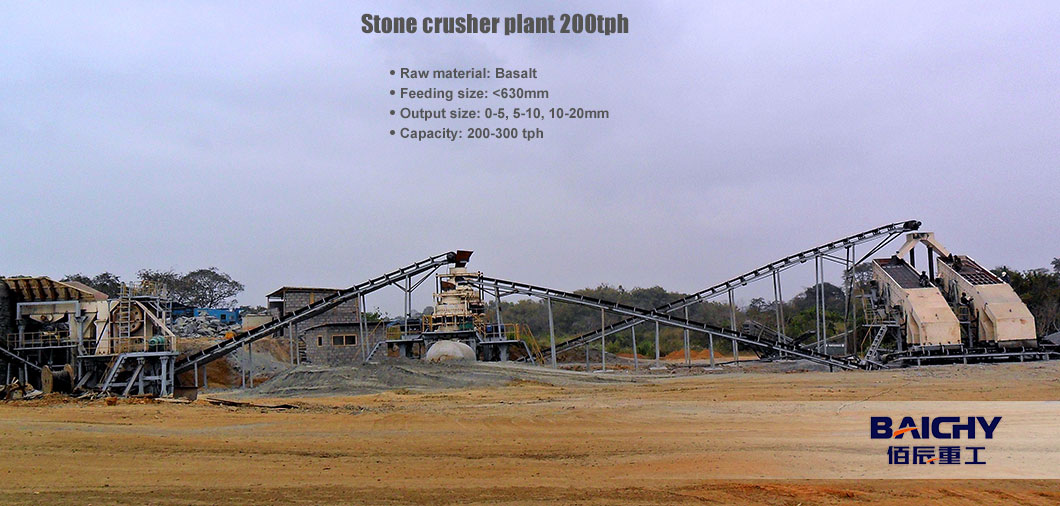

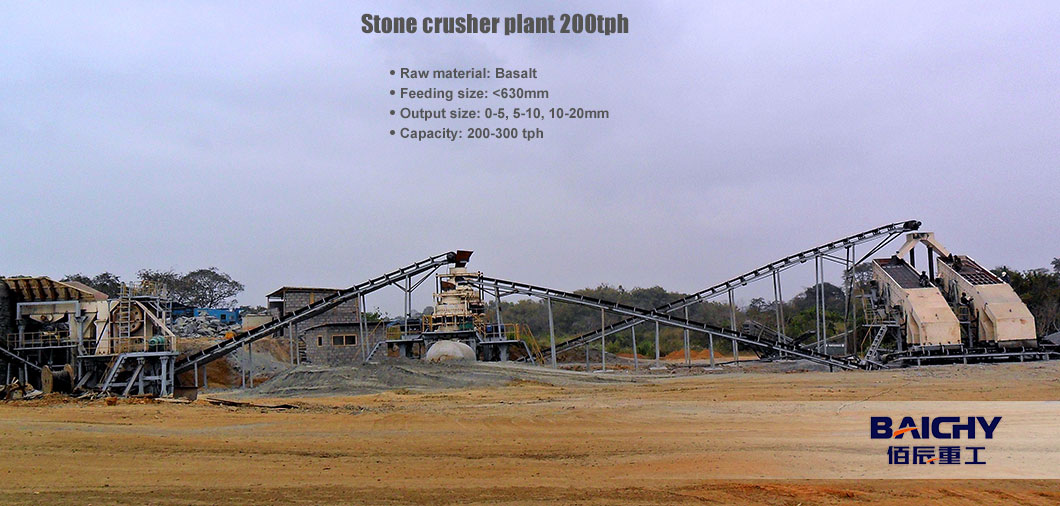

Case: Cone crusher PYB1200 for Basalt Stone Crushing Plant

Basalt could be used in construction (for building blocks or in the groundwork) and making cobblestones. In 2-stage basalt stone crusher plant, cone crusher is an important crushing equipment as secondary crusher. It makes use of the best coordination of crushing frequency and eccentricity, which enables the crushed materials much more fine and good shape. The crushed basalt size could be classified into 0-5mm, 5-10mm, 10-20mm. This is our site in Africa. Two sets cone crusher are chose for more efficiency and higher capacity.

People Also Frequently Asked For- FAQ

Firstly, gyratory crushers are designed for crushing very large materials - normally in the primary crushing stage, while cone crushers are typically used for secondary or tertiary crushing to make smaller, finer products. Secondly, the shape of the crushing head is different.

Which is better cone crusher or jaw crusher?

Due to the crushing principle, cone crusher has better grain shape than jaw crusher. Generally, you need shaping equipment after jaw crusher for better grain shape. And cone crusher can be used for shaping because of the adoption of lamination crushing principle, which makes the final products have good cubical shape.

What is the difference between impactor and cone crusher?

The main difference between an impact crusher and a cone crusher is that an impact crusher uses impact force to crush material, while a cone crusher uses pressure to crush material. Impact crushers typically use high-speed rotating hammers to crush material, while cone crushers use a spinning conical head.

What is Symons cone crusher?

Symons cone crusher is also called compound stone cone crusher. It's semi hydraulic and semi spring cone crusher to crush mid-hard and above mid-hard ores and rocks efficiently. It is an improved, optimized and updated replacement product of spring cone crusher.

2025-04-14

2025-04-14

86-15093113821

86-15093113821

86-15093113821

86-15093113821