Ball mill is an important grinding equipment after the material coarse-crushed. It is widely used for cement, the silicate produce, new type building material, chemical fertilizer, black and non-ferrous metal glass, ceramic and etc. It also can be used for the dry and wet grinding for all kinds of ores . Ball Mill is divided into single chamber, two chambers and multi- chambers according to the material and fineness. Ball mills can be dangerous if not used properly. Let’s study the precautions from installation, commission and operation.

Ball mill is divided into the right rotating and the left rotating, users can choose according to the actual situation, and also notes when signing the contract.

How to installation of feed part and discharge part?

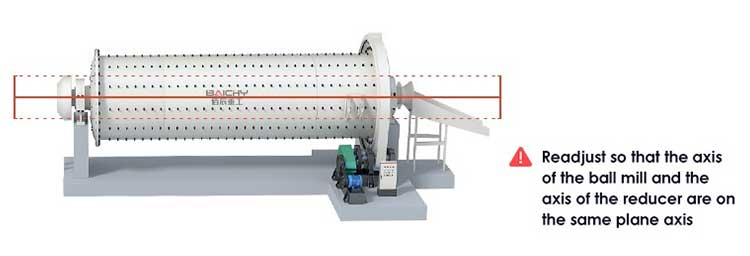

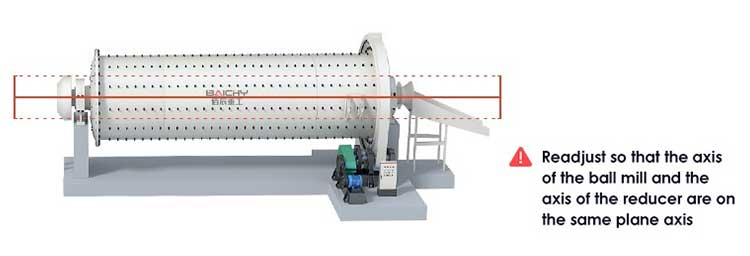

Keep feed bin and discharge tube in a line with the axial line of rotary part. And its horizontal height should be reached by adjusting shim. At this moment, turn shell slowly.If no twist and vibrating happen to feed bin and discharge tube, it indicates they have been fitted properly. So tighten the bolts now.

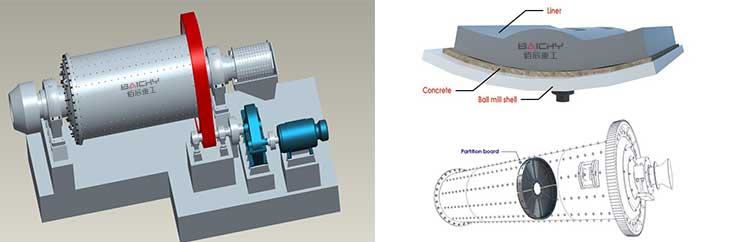

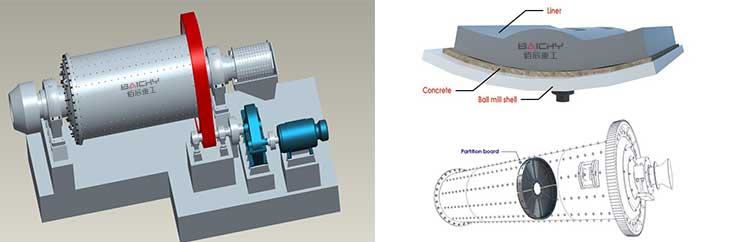

How to install ball mill liner plate?

1.Please clear dirty away inside shell before installing liner plate. Too big gap space between liner plates is not allowed. Do not install them reversely for special liner plates.

2.Please fill up seal packing and gasket for fastening liner plates’ bolts to prevent mineral powder from leaking.

3.Please spread layer of cement plaster(1:2) on inwall of shell before installing liner plates.Then tighten bolts.Gap space between each board should not be over grates’gap before installing dividing grate or separating storehouse board.

The machine starts to commission after the machine finishes the installation and meets all the requirements, the procedure as follows:

1. Ball mill runs emptily for 24 hours(without feeding grinding media)

2. Feeding 1/3 grinding media and also feeding material, then the machine runs for 8 hours.

3. Feeding 2/3 grinding media and also feeding material, then the machine runs for 72hours.

When commissioning,attention should be paid to the temperature of the rotating parts. The drive bearings, main bearings and gearboxes should also pay attention to whether the oil supply of the lubrication points is normal, whether the motor load, large and small gears, and the sound of the gearbox are normal, etc.

After commission, ball mill must meet operating standards, and operating rules and maintenance and repair rules must be formulated according to the actual situation, so that the machine can operate normally.

Ball mill operating procedures

1.Before starting, clear the debris around ball mill and check safety measures .

2.Check whether there is person or not within the mill and dangerous place.

3. Check whether the distance from the grinding shell surface to plate center(that is filling rate) meets requirement or not.

4.The manhole cover should be firmly and tightly fixed.

5.Check whether grinding body liner bolts and the bolts connecting the grinding head and shell is loosen or not.

6.Check whether the lubrication of the lubricating points is enough or not.

7.During initial commissioning or long-term shutdown, the hollow shaft must be lubricated before starting.

8.Rotating the shell by hand for a circle, only after check without contact and rotating smoothly , then start to use the motor.

Steps for Starting ball mill

a. Starting the discharging conveying equipment

b.Starting the mill

c.Starting feeding equipment of the mill

Steps for Stopping ball mill

1. Stopping the feeding material equipment

2.Stopping the mill

3.Closing the discharging material conveying system

Other precautions for grinding ball mill

1. Long-time stop grinding, the ball should be removed, avoiding the grinding shell bending.

2. Should always check the lubrication of the main bearing

3. After stopping the mill, turn the mill for half a circle every 5-10 minutes, until the mill is full cooling

People Frequently Asked For- FAQ

What is ball mill wearing parts

1. Non-standard ware parts: Liner plate (liner plates of shell, feed end, discharge end and diaphragms), balls and rods.

2. Standard ware parts: bridge bearings (bearing equipped with pinion gears)

3. Pinion gears

4. Lining for feeding and discharging

5. Spherical tile of tile mill or self-aligning rotor bearing.

What is a ball mill used for?

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

How fine does a ball mill grind?

The standard particle size of ball mill grinding varies depending on the ore and the process used, but it typically ranges from several micrometers to several millimeters. The final product particle size is often controlled by the size of the grinding media and the duration of the grinding process.

What is the best media for ball milling?

440C stainless steel grinding media balls have the highest strength and wear resistance among all the stainless steel alloys due to its high carbon content. The high wear resistance and strength make it a good choice for milling media, 440C is also used for ball bearings and valve parts.

2025-06-28

2025-06-28

86-15093113821

86-15093113821

86-15093113821

86-15093113821