If you’re in the aggregates, mining, or construction industry, you know that a jaw crusher’s performance hinges on one critical factor: the Closed Side Setting (CSS). This gap between the fixed and moving jaws determines your final product size, efficiency, and even equipment lifespan. But how do you adjust it correctly? In this guide, we’ll break down everything you need to know about adjusting jaw crusher gaps—from what CSS is to step-by-step methods for different crusher models.

What Is Jaw Crusher Gap (Closed Side Setting - CSS)?

The Closed Side Setting (CSS) is the smallest distance between the fixed jaw and the moving (swing) jaw at the bottom of the crushing chamber. Simply put, it’s the gap that defines the smallest particle size your jaw crusher will produce.

- A larger CSS means coarser output (e.g., 100mm rocks).

- A smaller CSS means finer output (e.g., 20mm gravel).

This setting is not just about product size—it directly impacts throughput, energy usage, and wear on jaw plates. That’s why regular adjustment is key.

Why Adjust the Jaw Crusher Gap?

1. Control Product Size: If your output is too coarse or too fine for your needs, adjusting the CSS fixes this.

2. Compensate for Wear: Over time, jaw plates wear down, widening the CSS and making output coarser. Adjustments restore the desired gap.

3. Optimize Efficiency: A properly set CSS ensures the crusher works within its design limits, reducing energy waste and preventing jams.

4. Adapt to Material Changes: Switching from hard rock to softer aggregates? Adjusting the CSS ensures optimal crushing for the new material.

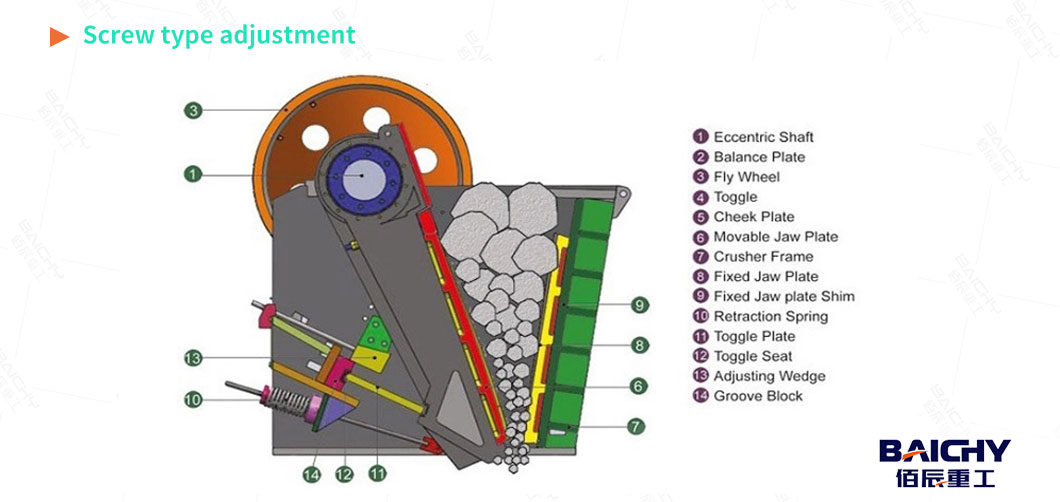

How to Adjust the Jaw Crusher Gap: 3 Common Methods

Jaw crushers use different adjustment mechanisms depending on their design and age. Below are the three most common methods, along with step-by-step instructions.

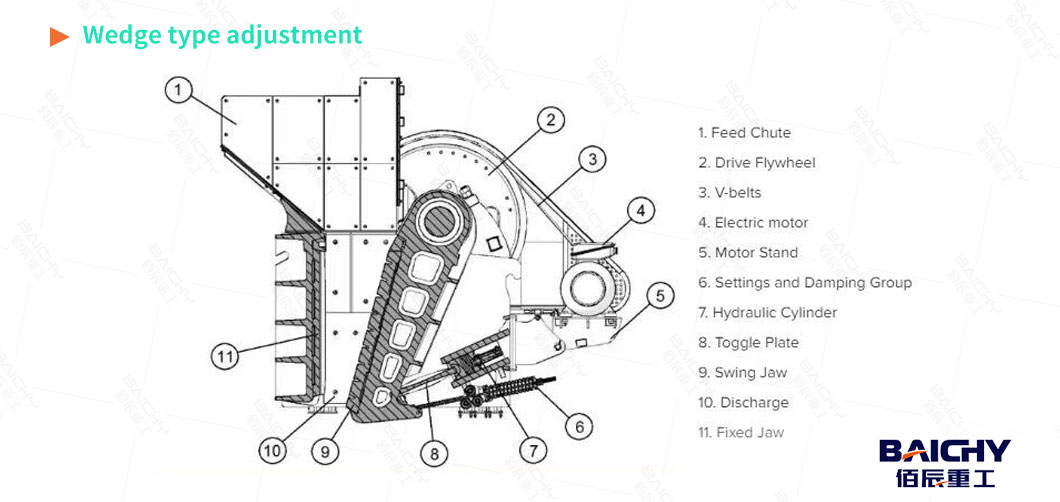

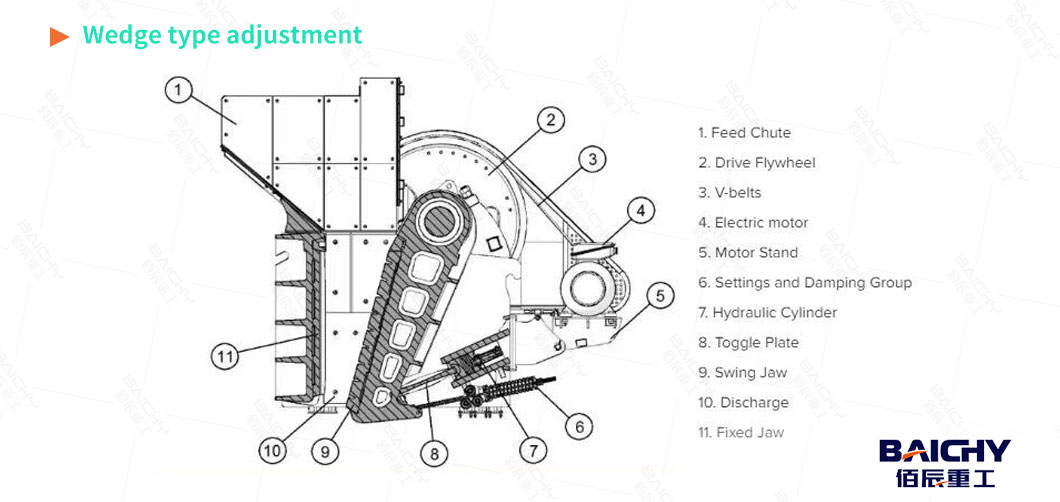

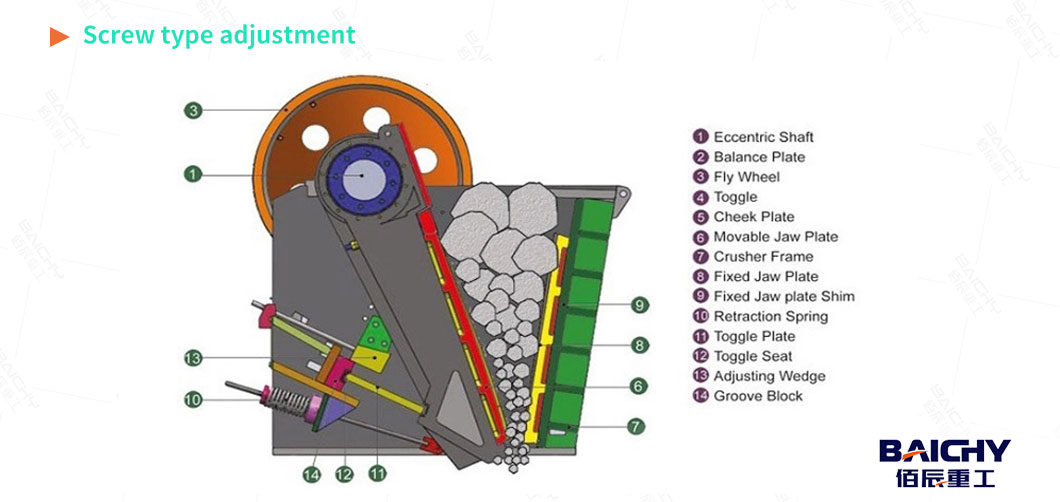

1. Wedge Adjustment (Most Modern Crushers)

Wedge adjustment is the standard for modern jaw crushers (e.g., Metso Nordberg® C Series, Sandvik, Terex, Baichy CJ jaw crusher). It’s precise, efficient, and widely used in small to large-scale operations.

● How It Works:

A set of wedges (or shim plates) sits behind the moving jaw. Tightening or loosening bolts moves these wedges, shifting the moving jaw closer to or farther from the fixed jaw—adjusting the CSS.

● Step-by-Step Guide:

- Safety First: Turn off the crusher, lock the power source, and wait for all moving parts to stop. Wear gloves, goggles, and steel-toe boots.

- Loosen Locking Bolts: Locate the tension rod nuts or locking bolts securing the wedge assembly (usually at the rear of the crusher). Loosen them to allow movement.

- Adjust the Wedge:

- To decrease CSS (finer output): Turn the adjustment bolts clockwise to move the wedge inward (toward the fixed jaw).

- To increase CSS (coarser output): Turn the bolts counterclockwise to move the wedge outward (away from the fixed jaw).

- Tighten Locking Bolts: Once the desired gap is set, retighten the locking bolts to secure the wedge in place.

- Verify the Gap: Measure the CSS (see “How to Measure” below) to confirm accuracy.

- Check Tension: Ensure all bolts and tension rods are secure before restarting the crusher.

*Note: Some models use shim plates instead of wedges. The process is similar—add shims to reduce the gap, remove them to increase it.*

2. Hydraulic Adjustment (Large, Advanced Crushers)

Hydraulic adjustment is found in high-capacity, modern crushers (e.g., Sandvik QJ341, Metso LT1213). It’s fast, precise, and ideal for operations needing frequent adjustments.

● How It Works:

Hydraulic cylinders control the position of the moving jaw. By extending or retracting these cylinders, you adjust the CSS with minimal manual effort.

● Step-by-Step Guide:

- Safety First: Power down the crusher, lock out the power, and ensure the chamber is clear of material.

- Access the Hydraulic Panel: Locate the control panel (usually near the adjustment cylinders) and power it on.

- Adjust the Cylinders:

- To decrease CSS: Retract the hydraulic cylinder to pull the moving jaw closer to the fixed jaw.

- To increase CSS: Extend the cylinder to push the moving jaw away.

- Monitor the Gap: Use the panel’s digital display (if equipped) or a measuring tool to check the CSS in real time.

- Lock the Setting: Once set, engage the hydraulic lock to prevent movement during operation.

- Test Run: Restart the crusher at low speed to ensure smooth operation.

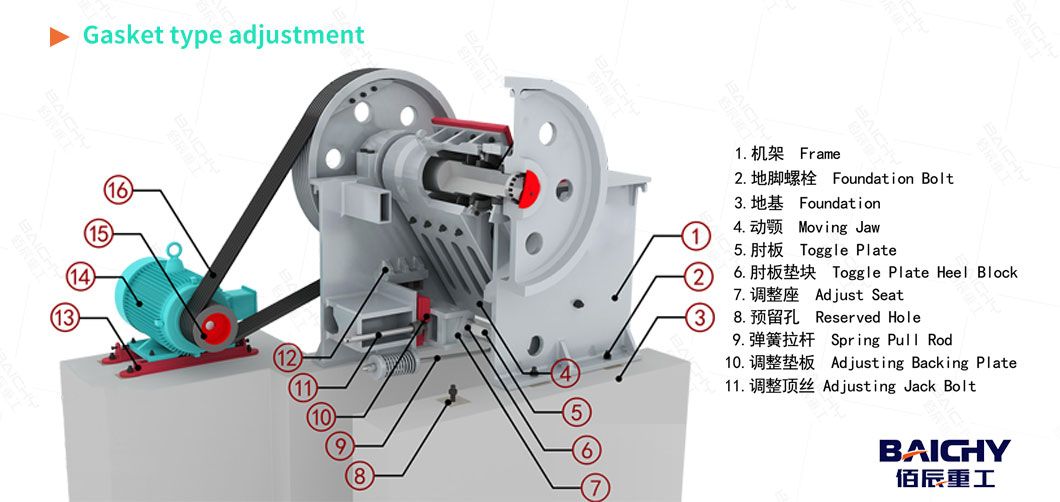

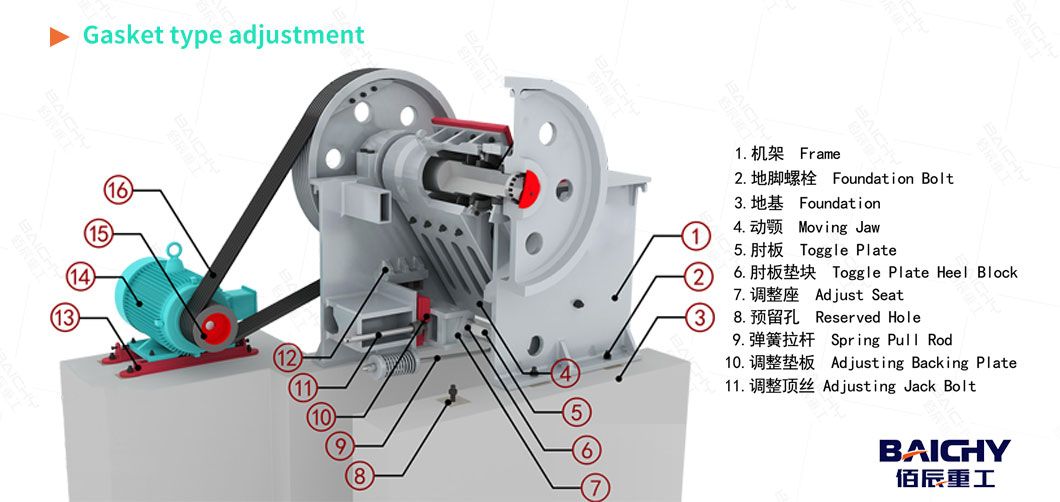

3. Toggle Plate Adjustment (traditional / Simple Crushers)

Older or smaller jaw crushers (e.g., traditional PE series jaw crusher) often use toggle plate adjustment. It’s less precise but still effective for basic operations.

● How It Works:

The toggle plate connects the moving jaw to the crusher frame. Adding or removing shims behind the toggle seat shifts the moving jaw, adjusting the CSS.

● Step-by-Step Guide:

- Safety First: Shut down the crusher, lock the power, and clear residual material from the chamber.

- Remove the Toggle Plate: Loosen the bolts securing toggle plate (located behind the moving jaw) and carefully remove it.

- Add/Remove Shims:

- To decrease CSS: Add steel shims behind the toggle seat to push the moving jaw forward.

- To increase CSS: Remove shims to let the moving jaw shift back.

- Reinstall the Toggle Plate: Replace the toggle plate and tighten all bolts securely.

- Measure the CSS: Confirm the gap with a measuring tool (see below).

- Check for Stability: Ensure all components are tight to avoid vibration during use.

Final Thoughts

Adjusting the jaw crusher gap (CSS) is a simple yet vital task for maintaining product quality and equipment health. Whether you’re using a wedge, hydraulic, or toggle plate system, the key is precision, safety, and regular checks. By following this guide, you’ll keep your crusher running efficiently and your output consistent—saving time, money, and headaches in the long run.

Need more help? Consult your crusher’s manual or contact the Henan Baichy Machinery Equipment Manufacturer for model-specific advice

Frequently Asked Questions: About Jaw crusher

1. What is the gap of a jaw crusher?

A Jaw Crusher is sized so that the maximum feed size is 80% of the gape and width openings. The gape is the measurement between the two jaw dies, while the width is the measurement between the two side plates.

2. What is the close side setting on a jaw crusher?

First off, for those new to crushing, the closed-side setting (CSS) on a jaw crusher is the distance between the jaw liners at the bottom of the crushing chamber when the machine is operating. The CSS determines the product size of the material produced by the jaw.

3. What is the wedge in the jaw crusher?

Jaw wedges, also known as jaw plates, are the components of a jaw crusher that facilitate the crushing process. Positioned between the stationary and moving jaw, they are responsible for holding and breaking down material effectively.

A lump of lead, whose dimensions are greater than the gap of the crusher, is lowered through the crusher while the crusher is running. The lead is pulled back through the crusher very slowly to be sure that it is flattened as far as it can be. The narrowest point on the lead is then measured

2026-01-15

2026-01-15

86-15093113821

86-15093113821

86-15093113821

86-15093113821