Quarry mining crushing equipment refers to a variety of machinery specifically designed to break down large rocks, stones, and ore extracted from quarries into smaller, more manageable pieces. These pieces can then be further processed or directly used in various industries.

A quarry crushing plant typically operates in stages (primary, secondary, tertiary) to achieve the desired size and shape of aggregates. Here’s a breakdown of essential equipment:

Quarry mining crushing equipment refers to a variety of machinery specifically designed to break down large rocks, stones, and ore extracted from quarries into smaller, more manageable pieces. These pieces can then be further processed or directly used in various industries. Here are the main types and their characteristics:

1. Jaw Crushers

- Working Principle: A jaw crusher is typically used as a primary crusher in quarry mining operations. It has a fixed jaw and a movable jaw. The material is fed into the crushing chamber between these two jaws. As the movable jaw moves back and forth (powered by an eccentric shaft and toggle - plate mechanism), it squeezes the rock against the fixed jaw, gradually reducing the size of the material through compression.

- Features: They can handle large - sized feed materials, with some models able to accept rocks up to 1200mm in size. Jaw crushers are known for their high crushing ratio, durability, and simplicity of operation, making them suitable for crushing hard and abrasive materials like granite, basalt, and quartzite.

2. Cone Crushers

- Working Principle: Cone crushers are often used in secondary or tertiary crushing stages. They operate based on the principle of compression and shearing. Inside the crusher, there is a mantle that gyrates eccentrically within a concave bowl. The rock enters the crushing chamber and is gradually crushed between the mantle and the concave as the mantle moves, reducing the particle size.

- Features: These crushers produce a more uniform and cubical - shaped product, which is highly desirable for applications such as road construction and concrete production. They are capable of handling high - volume operations and can process a wide range of materials, from medium - hard to very hard rocks. Modern cone crushers often come with hydraulic adjustment systems that allow for easy control of the discharge opening, enabling operators to adjust the final product size.

3. Impact Crushers

- Working Principle: Impact crushers use the force of impact to break down materials. The rock is fed into the crusher and is accelerated by a high - speed rotor equipped with blow bars. The accelerated material is then thrown against impact plates located inside the crushing chamber, causing it to shatter into smaller pieces. Multiple impacts may occur as the material bounces back and forth between the blow bars and the impact plates.

- Features: They are particularly effective at producing fine - sized aggregates with a good shape, making them suitable for applications where high - quality finished products are required. Impact crushers are relatively energy - efficient and can handle materials with varying degrees of hardness. However, they may not be the best choice for extremely abrasive materials, as the wear on the blow bars and impact plates can be significant.

4. Hammer Crushers

- Working Principle: Hammer crushers operate by using a set of rotating hammers. The material enters the crusher and is struck by the rapidly rotating hammers, which break the rock into smaller pieces. The hammers can be fixed or swing freely on the rotor shaft. The crushed material then passes through a screen at the bottom of the crusher, which controls the final product size.

- Features: Hammer crushers are relatively simple in design and are cost - effective for crushing medium - hard and brittle materials. They are often used in applications such as coal crushing, limestone crushing for cement production, and in some small - to - medium - scale quarry operations. However, they may not be suitable for very hard or abrasive materials due to the relatively high wear on the hammers.

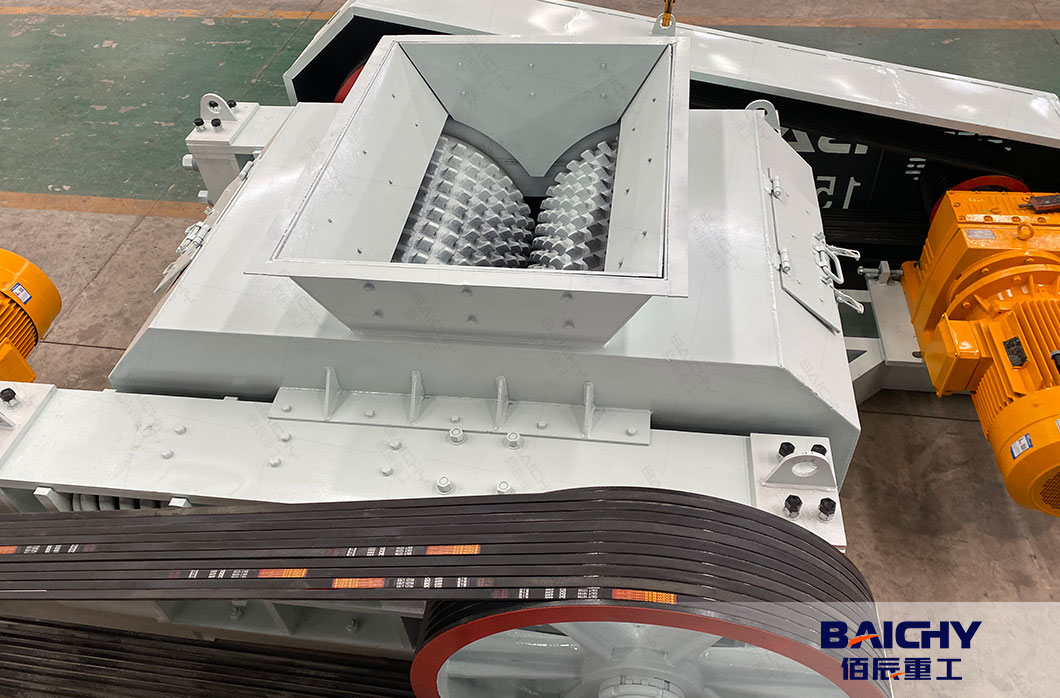

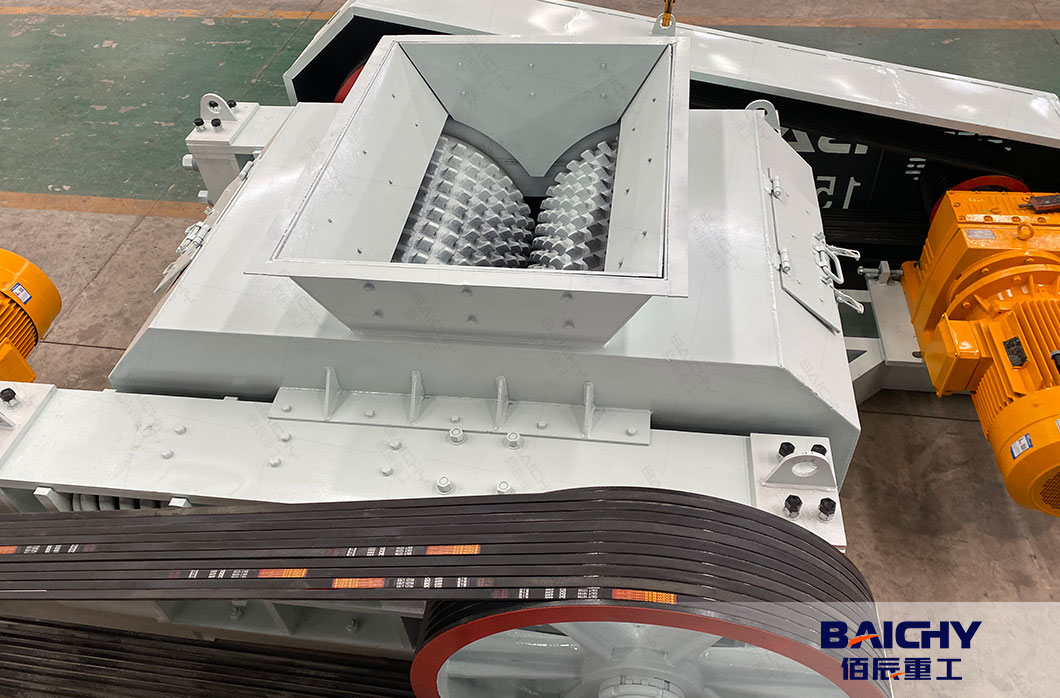

5.Double Roller Crushers

- Working Principle:Dboule roller crusher features two counter - rotating rollers. As materials enter the gap between them, the rollers' squeezing and shearing action crushes the rocks. The distance between the rollers can be adjusted to control the output size.

- Features: Double roller crushers are efficient for producing fine - grained products, especially suitable for processing relatively soft to medium - hard materials. They are compact, easy to operate, and have low maintenance requirements, making them a good choice for small - to - medium - scale quarry operations or for applications where precise particle size control is needed.

6.Other relative machines

- Feeders: Regulate feed to crushers and remove undersized material.

- Conveyors: Transport material between crushers, screens, and stockpiles. Belt scales and dust covers are often integrated.

- Control Systems: Monitors and adjusts crusher settings, feed rates, and screen sizes in real time.

- Dust Suppression Systems: Minimize airborne particles using water sprays or misting cannons.

- Washing Plants: Clean aggregates to remove clay or silt (common in sand production).

- Surge Bins: Buffer material between stages to prevent bottlenecks.

These quarry mining crushing equipment are essential for transforming raw materials extracted from quarries into valuable aggregates and processed products that are used in construction, road building, infrastructure development, and many other industries. Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Stone crusher is one of its core production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you are interested in the stone crusher, please click on the online consultation to contact us. Baichy Machinery is dedicated to serving you 24 hours a day!

2025-04-18

2025-04-18

86-15093113821

86-15093113821

86-15093113821

86-15093113821