Before know types of stone crushers, let’s know about stone crushing plant first. Stone crusher plant can be classified into four stages depending on the degree to which the starting material is fragmented. These four stages are primary, secondary, tertiary and quaternary stages. In order to control the finished size and quality of the product and reduce wastage as well, you must ensure that the reduction of aggregates is evenly spread over the four stages.

So, how many types of stone crusher exactly are there?

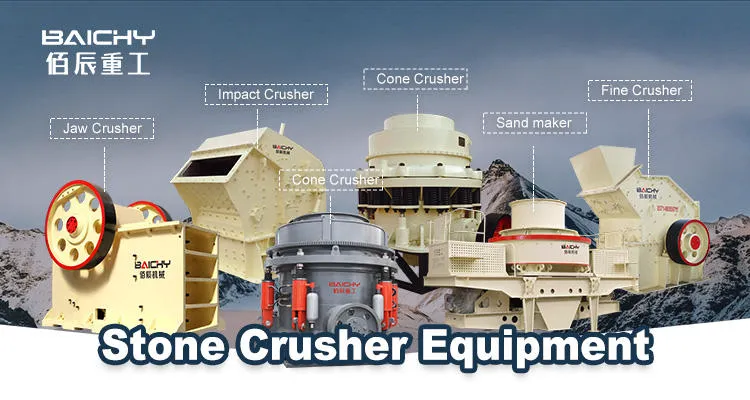

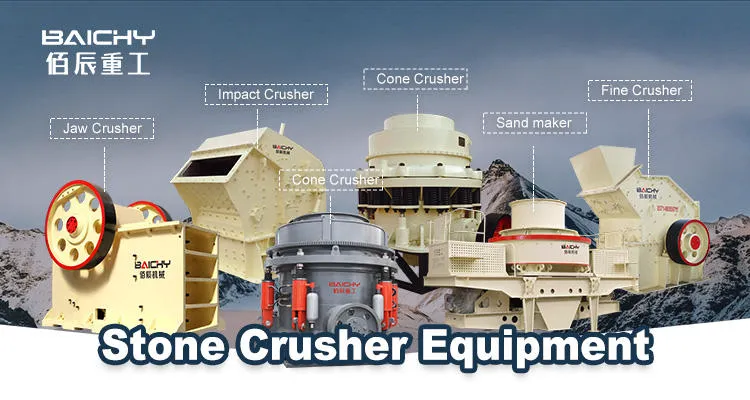

The basic crusher types are: jaw crusher, cone crusher, impact crusher roller crusher, hammer mill crusher, which are operating in different stage based on their character.

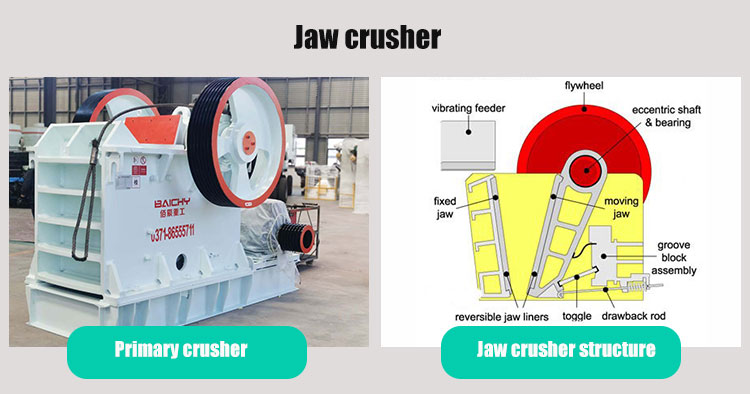

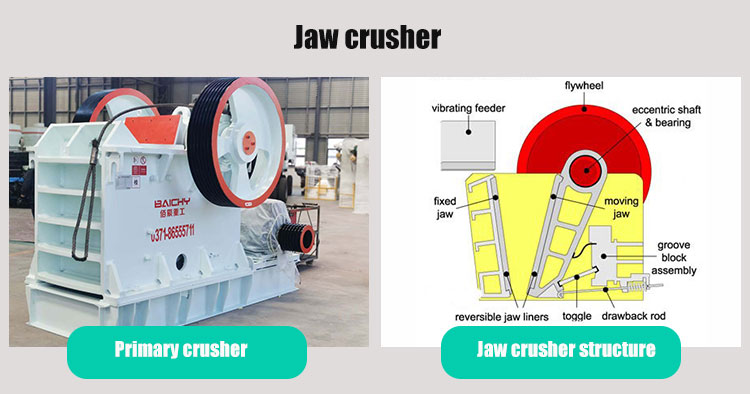

Jaw crusher uses compressive force and the materials are allowed into a gap at the top of the equipment between two jaws. Then it discharges from the bottom until it become small enough by the force of jaw plates forces.

Jaw is popular crushing machine because it crushes big rocks into smaller sizes easily. It can work on a range of stone from the softer ones like limestone, dolomite, clay, gypsum to harder basalt, granite, quartz, andesite, even concrete with little reinforcement bar. Thus, it proves itself as an effective primary crusher in aggregate, mining, recycling, and concrete industries.

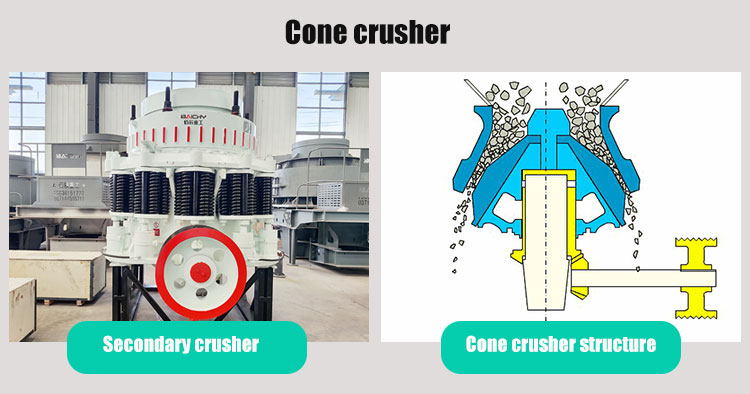

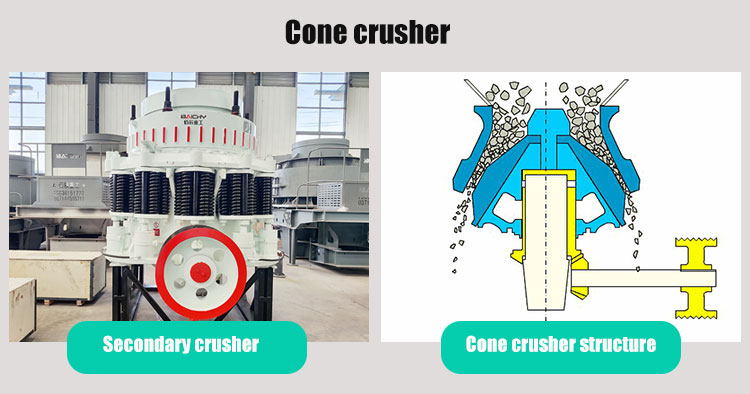

Cone crusher uses a rotating cone inside a crushing chamber to break up the rocks. The rotating mantle in a concave bowl is lined with manganese to be more wearing. It works by compression to reduce materials by squeezing them until they break apart. The pieces are continually crushed until they are small enough to move through the narrow opening at the bottom of the crusher.

Cone crusher could crush medium-hard to very hard and abrasive rocks, like river stone, pebble, granite, basalt etc. Cone crushers are typically applied in secondary and tertiary crushing stages. The cone crusher is renowned for providing a very high content of cubic material in the finished product. If you need your finished products to be much smaller in size and perfect in shape, choose the cone crusher.

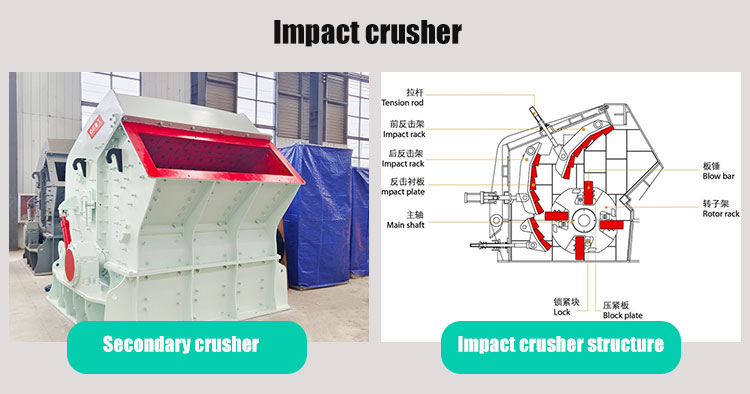

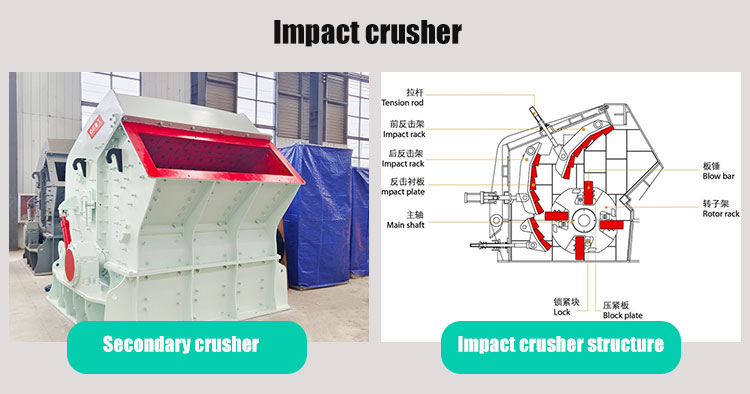

Impact crusher is also caleed horizontal shaft impactors (HSIs). This type machines crush stones by the impacting forces of certain wear parts known as blow bars and impact plates or toggles.They are suitable to crush sedimentary deposit such as limestone and softer rocks. It is used in secondary crushing stage.

The advantages of impact crushers is their versatility in terms of input material and output size. There are many different designs out there but generally speaking impact crushers can produce material from 700mm down. The smaller the input material the harder it gets to crush. The output gradation can be adjusted through various settings.

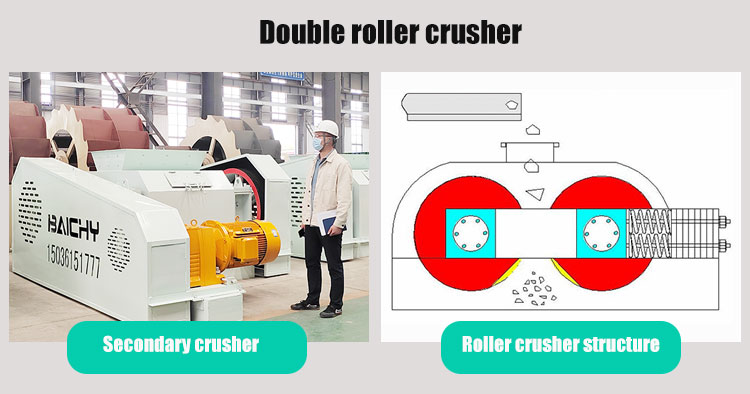

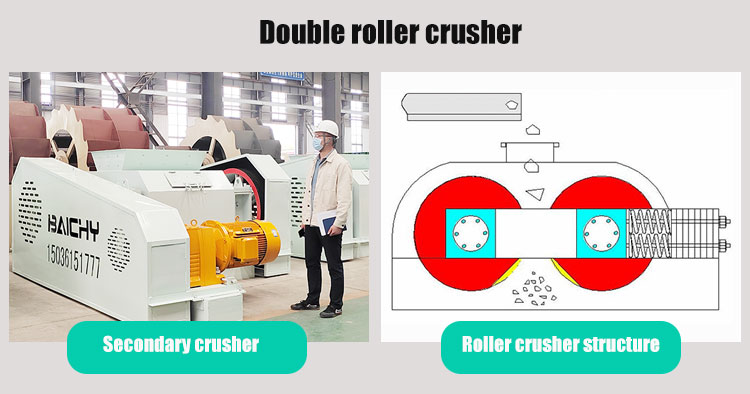

A roll crusher is a type of crushing equipment used to reduce the size of materials by compressing feed material between two cylindrical rollers that rotate in opposite directions. It has types of smooth roller crusher and teeth roller crusher according to cylindrical surface.

Roller crusher is designed to handle secondary or tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries.

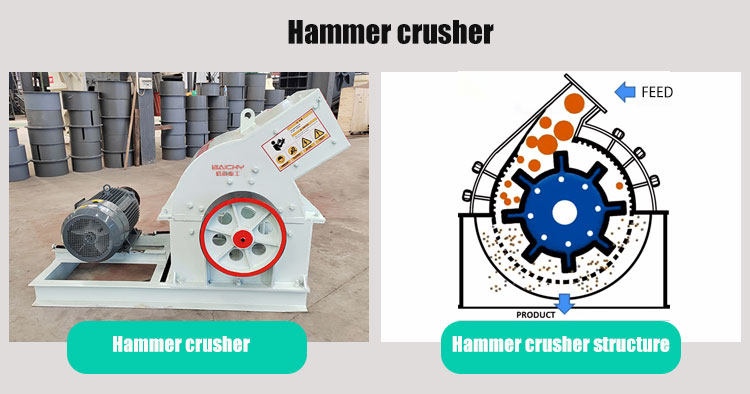

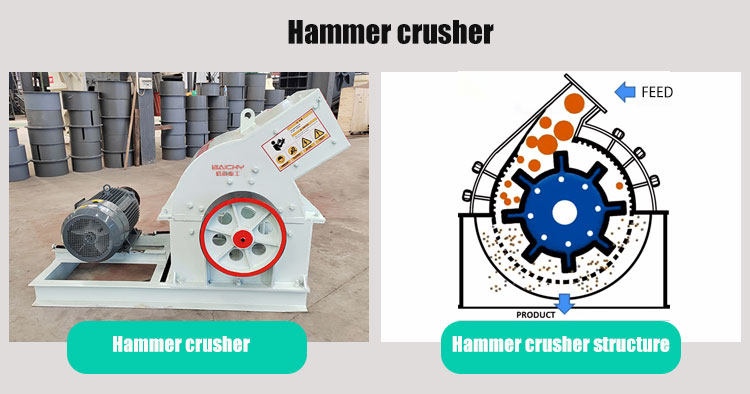

A hammer crusher is type of ore crushing equipment. It uses high-speed rotary hammers to hit medium-hard brittle materials with low water content, such as limestone, gypsum, slag, coke, coal, shale, gypsum etc. The main working part of hammer crusher is rotor assembly with hammer head.

Hammer crusher is characterized by high crushing ratio (generally 10 to 25 some times up to 50). It uses high-speed rotary hammers to crush rock into powder size. So it widely used in cement manufacturing, chemical, electric power, building material industries.

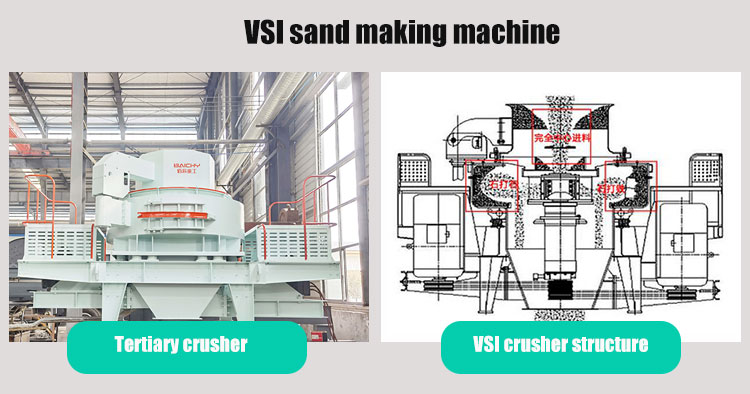

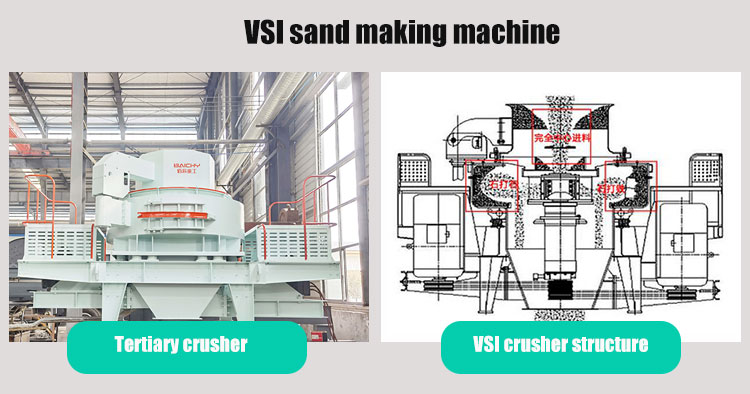

Vertical Shaft Impact Crusher or VSI Crusher are one type of impact crushers. which offer higher reduction ratios at a lower energy consumption. The material is crushed as it hits the liners of the outer body at high speed and also due to the rock-on-rock action. VSI sand making machine is mainly used in the production of fine materials, including sand with a good cubical shape.

VSI crusher is used as a tertiary stage crusher to get high ratio of fine material and to give cubical shape to the products that are coming through the secondary crushers. Any type of materials, especially the hard stones such as basalt and granite with maximum 45 mm size which are crushed by secondary crushers could be fed to Vertical Shaft Impact Crushers to get finer good shape materials.

Above all, primary and secondary stages involve crushing of coarse materials while the tertiary and quaternary stages involve the reduction of ore particles to finer degrees. Activities at the primary stage will depend on gyratory, jaw or impact crushers. Cone crushers, roll crushers and impact crushers are mostly used at the secondary stages. The tertiary and quaternary stages mostly require the utilization of cone crushers, although some functions may require vertical-shift impact crusher.

When you want to process sand, gravel, minerals, rock, or other aggregate products, it is important to work with a capable and professional material handling equipment design and engineering company dedicated to selling and installing the best new stone crushers for your needs. Baichy Machinery Company works closely with its customers to determine the best, most cost-effective, efficient size reduction method and equipment for specific applications. Support services include system design and 24-hour parts and service. You could click here to get expert reply for crushing plat design and latest price list.

People also frequently asked(FAQ):

Which crusher is best for stone?

Stone crusher is an indispensable part of quarry crushing or mining plants to produce construction material, such as base gravel or concrete and asphalt mixes. According to different feeding and discharging size of materials, different crushers are chosen.

What are the different types of stone crushers?

All rock crushers can be classified as falling into two main groups. Compressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material. Jaw crushers, cone crusher, roller crusher is operated according to the compression principle. Impact crushers, hammer crusher, VSI hammer utilize the impact principle.

Which is better cone crusher or jaw crusher?

Both cone crusher and jaw crusher are popular durable efficient crusher equipment to crush hard stone. Jaw crusher is an effective primary crusher, while cone crushers are typically applied in secondary and tertiary crushing stages.

How do l choose a stone crusher?

To choose a suitable crusher, you’ll need to provide information about the material you plan to crush.

1.The abrasiveness and hardness of the material determine the compressive strength it can withstand before crushing.

2. The material feeding size is to determine the size of the crusher required.

3. The finished material size is required to determine the number of crushing stages necessary to achieve the desired reduction.

4. Capacity (throughput) is measured in tons per hour. You will need to determine the processing capacity

2025-04-13

2025-04-13

86-15093113821

86-15093113821

86-15093113821

86-15093113821