A stone crusher plant needs to meet several requirements, which mainly include which mainly include site selection, equipment, safety, Operational management and financial considerations. Now let’s study the details for these aspects:

1.Site selection requirements:

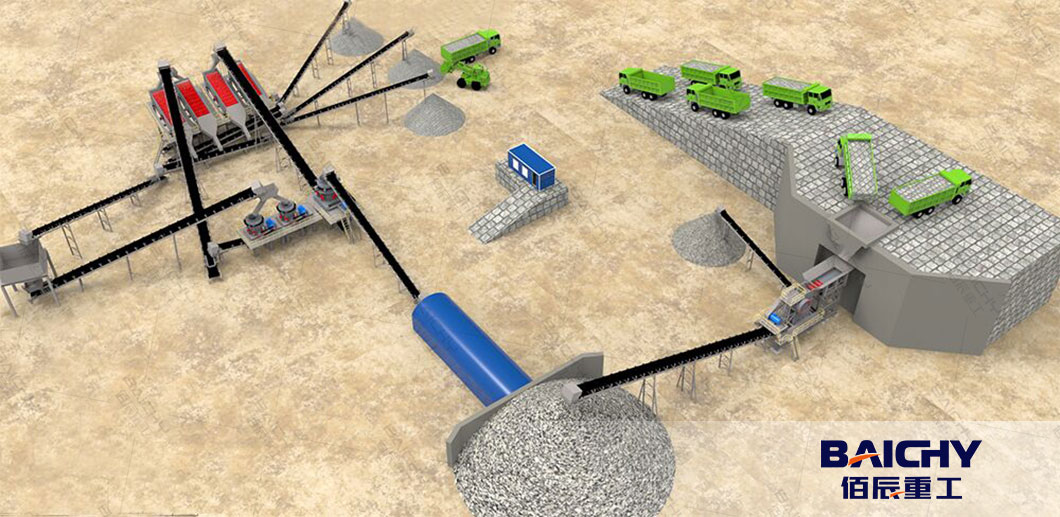

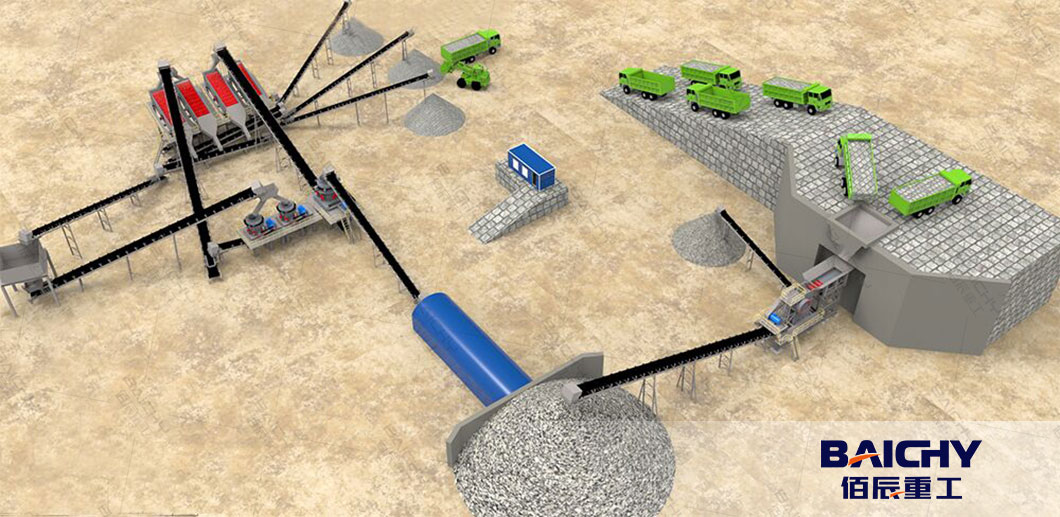

1-1.Sufficient space: The crusher plant requires a certain area of land to accommodate various equipment such as crushers, conveyors, and screening machines, as well as to reserve space for raw material storage and finished product stacking. The site should be able to reasonably layout all the facilities of the plant2.

1-2. Proximity to raw materials and markets: It is better to be close to the source of raw materials to reduce transportation costs and time. At the same time, being close to the market can also facilitate the timely delivery of products6.

1-3. Environmental factors: The site should be located in an area that complies with environmental regulations, such as being away from residential areas, water sources, and nature reserves to minimize the impact on the surrounding environment. And it should be located in the downwind direction of the residential area to avoid dust and noise pollution affecting people's lives26.

1-4. Geological conditions: The geological conditions of the site should be stable, with good bearing capacity to ensure the stability of the equipment and plant buildings. Avoiding areas with soft soil, waterlogged areas, and areas prone to geological disasters is necessary2.

2.Equipment requirements:

2-1. Stone Crusher selection: Different types of crushers are suitable for different materials and particle size requirements. For example, jaw crushers are suitable for primary crushing of large pieces of materials, while cone crushers and impact crushers are suitable for secondary and tertiary crushing. The selected crusher should be able to meet the production capacity and product quality requirements of the plant6.

2-2. Conveyor and screening equipment: Conveyor belts are needed to transport raw materials and finished products between different equipment. Screening machines are used to screen out products of different particle sizes to ensure product quality. These auxiliary equipment should be matched with the crusher in terms of capacity and performance to form a smooth production line.

2-3. Dust removal and noise reduction equipment: Crushers generate a lot of dust and noise during operation. Dust removal equipment such as dust collectors and bag filters should be installed to reduce dust emissions and protect the environment. Noise reduction measures such as installing sound insulation covers and using low-noise equipment should also be taken to reduce noise pollution.

3.Safety requirements:

3-1. Equipment safety: The crusher and all related equipment should meet safety standards and regulations. There should be safety protection devices such as emergency stop switches, safety interlocks, and protective covers for rotating parts to prevent accidents and ensure the safety of operators13.

3-2. Electrical safety: The electrical system of the crusher plant should be designed and installed in accordance with electrical safety standards, with reliable grounding and short-circuit protection to prevent electrical hazards.

3-3. Operational safety: Operators should be trained to master the correct operation methods and safety precautions of the equipment, and strict safety management systems and operating procedures should be established to ensure safe production.

4.Environmental protection requirements:

4-1. Dust control: In addition to the dust removal equipment mentioned above, measures such as spraying water and sealing the production line can also be taken to reduce dust emissions and meet environmental protection standards.

4-2. Wastewater treatment: If there is wastewater generated during the production process, appropriate wastewater treatment facilities should be installed to treat the wastewater to meet the discharge standards before being discharged.

4-3. Vibration control: The operation of the crusher may cause vibration, which may affect the surrounding buildings and structures. Therefore, vibration isolation and damping measures should be taken to reduce the impact of vibration.

5.Operational management requirements:

5-1. Skilled operators: Operators need to have professional skills and experience to operate and maintain the crusher plant, and be able to deal with various problems in the operation process in a timely manner.

5-2. Regular maintenance: Regular maintenance and inspection of equipment are necessary to ensure the normal operation of the equipment, extend the service life of the equipment, and reduce equipment failure rates. Maintenance work includes lubrication, replacement of wearing parts, and inspection of electrical and mechanical systems.

5-3. Quality control: Establish a quality control system to monitor the quality of raw materials and finished products, and ensure that the products meet the relevant quality standards and customer requirements.

6. Financial Considerations:

6-1. Budget: Adequate funding for initial setup, including purchasing equipment and infrastructure development.

6-2. Operational Costs: Ongoing costs for maintenance, labor, utilities, and raw materials.

6-3. Contingency Fund:** Reserve funds for unexpected expenses or emergencies.

By addressing these requirements, a crusher plant can be set up to operate efficiently, safely, and in compliance with all relevant regulations. Baichy Machinery has a history of more than 20 years. It not only produces a full set of crushing and sand making equipment, but also provides EPC project general contracting services, including plant site selection and construction, production line design and installation, and production and operation technical training. Welcome to consult online to get your exclusive stone crushing plant solution.

2025-10-09

2025-10-09

86-15093113821

86-15093113821

86-15093113821

86-15093113821