Iron ore is a crucial raw material in the steel industry, and the process of extracting iron ore requires efficient crushing equipment. Iron ore stone crusher machines play a vital role in breaking down large rocks into smaller particles for further processing. Here are some common types of crushers used in the iron ore crushing process, each with its own advantages and considerations

1. Jaw Crusher- Robust Iron ore Crushing Machine

1-1.Working principle: The movable jaw plate makes periodic reciprocating motion on the fixed jaw plate. When the movable jaw plate approaches the fixed jaw plate, the material is squeezed, split and bent; when the movable jaw plate leaves the fixed jaw plate, the material that has been crushed to a size smaller than the discharge port is discharged, while the larger particles remain in the crushing chamber and continue to be squeezed and crushed next time.

1-2.Features: simple structure, durable, easy maintenance, low operating cost. It has a large crushing ratio, can initially crush large pieces of iron ore into smaller particles, can handle iron ores of various hardness, has a large feed size, and the maximum feed size can generally reach 1400mm.

1-3.Application scenario: It is commonly used for coarse crushing of iron ore. It is the first process in the iron ore crushing production line, providing a suitable feed size for subsequent crushing, screening and other processes.

2. Gyratory Cone Crusher - Efficient Iron Ore Crushing Machine

2-1. Working Principle: It consists of two truncated cones, a movable cone and a fixed cone. The main shaft of the movable cone is suspended on a fixed suspension point above the beam. Driven by the lower transmission mechanism, its cone head performs continuous eccentric gyratory motion around the main shaft, so that the ore between the two cones is squeezed, broken and ground, and the crushed product is discharged from the discharge port2.

2-2. Features: It works relatively smoothly, the equipment has light vibration, the continuous operation output is high, and the energy consumption is low. The product appearance is relatively neat, and the powder ore produced is less. The feed particle size is large, and the maximum feed particle size can generally reach 1000mm. It is suitable for processing a large amount of iron ore, with large production capacity, and can process more than 1200-5000 tons/hour of materials2.

2-3. Application scenario: It is mainly used for the coarse crushing of iron ore, especially for the iron ore crushing production line of large mines and steel enterprises. It can efficiently crush large pieces of iron ore into smaller particles, providing raw materials for subsequent medium and fine crushing processes.

3.Multi-cylinder Hydraulic Cone Crusher - Versatile

3-1.Working principle: The motor drives the eccentric sleeve to rotate through the transmission device, so that the mortar wall moves toward the crushing wall to squeeze the ore. The material is crushed by squeezing, bending and shearing between the two walls. The crushed material is discharged from the discharge port under the action of gravity. The hydraulic system can adjust the size of the discharge port and realize overload protection.

3-2.Features: Large crushing ratio: It can crush larger ore into smaller particles, effectively improving production efficiency. High degree of automation: It can automatically adjust the size of the discharge port and realize intelligent control according to the properties of the ore and production needs. Uniform product particle size: The particle size of the crushed ore is relatively consistent, which can meet the particle size requirements of different production processes. Stable and reliable operation: The multi-cylinder hydraulic system provides stable power, the equipment structure is solid, and the failure rate is reduced. Convenient maintenance: The modular design is adopted, and the parts are easy to replace, which can shorten the maintenance time and reduce the maintenance cost.

3-3.Application: Commonly used for secondary crushing and fine crushing of iron ore, especially for iron ore crushing production lines of large mines and steel enterprises, providing raw materials for subsequent screening and ball mill beneficiation and grinding processes

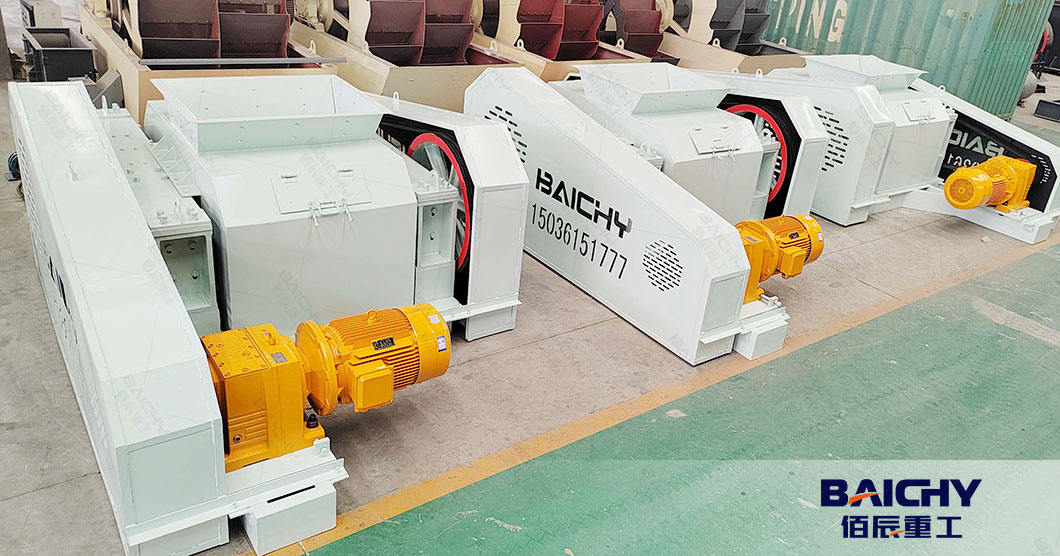

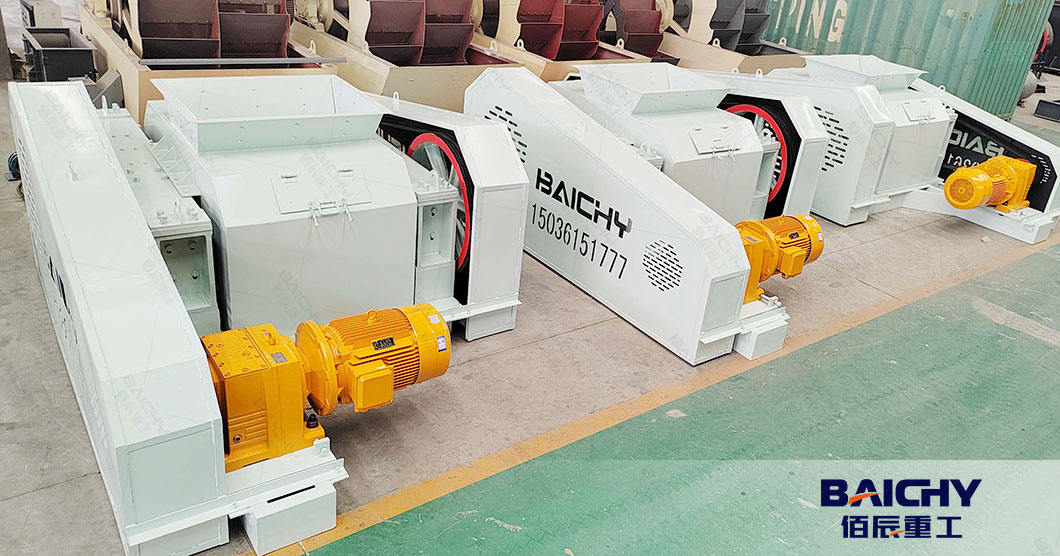

4. Hydraulic roller crusher - Reliable Iron Ore Crusher

4-1.Working principle: The material is squeezed and ground by two relatively rotating rollers. After the material enters between the rollers, it is squeezed and sheared by the rollers and crushed into smaller particles. The spacing between the rollers can be accurately adjusted by the hydraulic system to control the discharge particle size1.

4-2.Features: Hydraulic drive can accurately control the force, avoid excessive impact, reduce energy consumption, and improve crushing efficiency. The roller wheel is made of special wear-resistant materials with strong wear resistance, which prolongs the service life of the equipment and reduces the cost of frequent replacement of parts. The intelligent control system can dynamically adjust according to the hardness of the iron ore, automatically adapt to various operating conditions, compact structure, excellent noise control, and improved working environment1.

4-3.Application scenarios: Suitable for medium and fine crushing of iron ore, which can further crush the coarsely crushed iron ore into smaller particles to meet the requirements of different production processes, especially for iron ore with higher hardness, it has a good crushing effect.

The best crusher for iron ore crushing process will depend on the specific requirements of the operation, such as the desired end product size, capacity, operating costs, and the characteristics of the ore. It is important to consider factors such as efficiency, reliability, maintenance requirements, and cost-effectiveness when selecting the right crusher for iron ore crushing in a mining operation. Consulting with industry experts and conducting thorough research can help in making an informed decision on the best crusher for iron ore crushing process.

People Also Frequently Asked For - FAQ

1.How does an iron ore crusher work?

Iron ore is typically crushed in a two-stage process. First, the ore is subjected to a primary crushing process that reduces the size of the ore to a maximum size of about 6 inches. The crushed material is then transferred to a secondary crushing machine, where it is further reduced to a size of about 1/2 inch or less.

2. What are the three types of crushers?

Jaw Crushers: Ideal for heavy-duty primary crushing applications.

Cone Crushers: Perfect for secondary and tertiary crushing with precise output.

Impact Crushers: Suitable for various stages with impactful reduction.

3. What is the process of crushing iron ore?

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers.

2025-11-22

2025-11-22

86-15093113821

86-15093113821

86-15093113821

86-15093113821