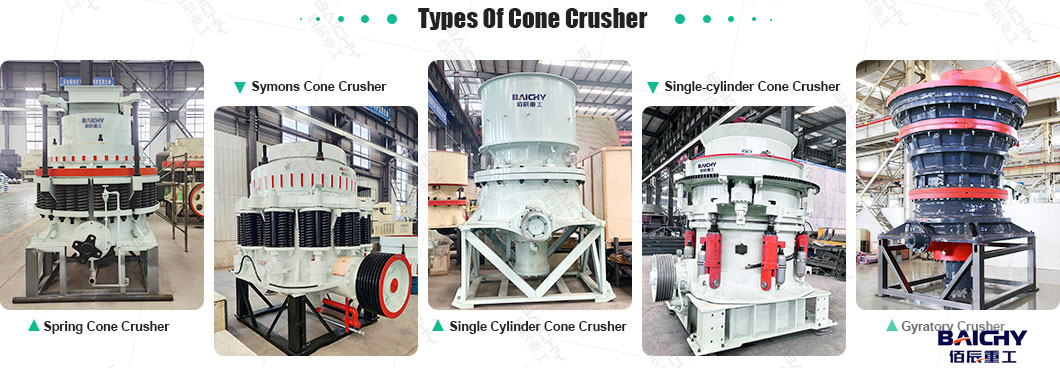

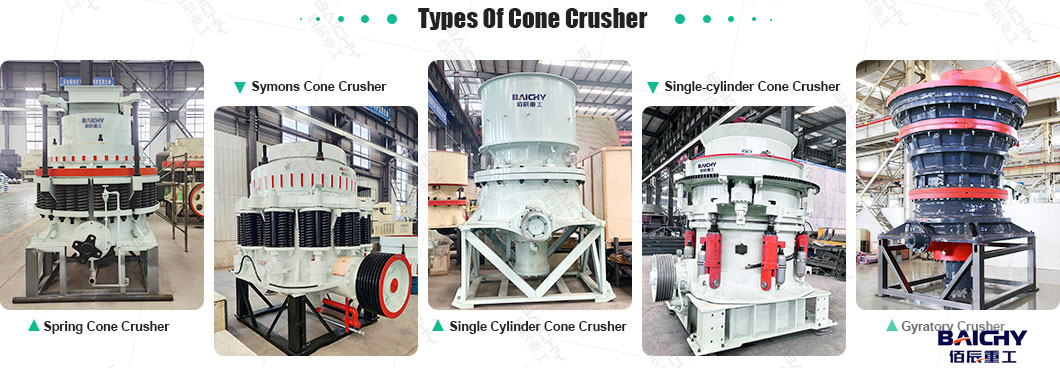

Cone crushers are used in mining and aggregate industries to crush rock and ore into smaller pieces. They work by compressing the material between a gyrating spindle and a concave hopper. It is very effective in fine crushing of hard ores, slag and refractory materials. Here are five types of cone crushers you should know:

- Spring cone crusher: Uses mechanical springs for adjustment and overload protection.

- Hydraulic cone crusher: Uses hydraulic systems for adjustment and protection; can be further divided into single-cylinder and multi-cylinder.

- Multi-Cylinder Hydraulic Cone Crusher: Uses hydraulic systems for adjustment and protection; The final product is more finer and better shape.

- Symons cone crusher: A specific design with a steep crushing chamber, available in standard and short head configurations.

-Gyratory cone crusher: Although similar to cone crushers, they are technically different but sometimes grouped together.

Spring Cone Crusher

Working Principle: It uses springs as the overload protection device. When uncrushable materials enter the crushing chamber, the springs compress to allow the movable cone to move away from the fixed cone, protecting the machine from damage.

Advantages: It has a relatively low cost, and the spring insurance system can effectively deal with the entry of iron blocks and other harmful substances. It adopts dry oil and water sealing forms, which are reliable and easy to maintain.

Disadvantages: The adjustment of the discharge port is relatively cumbersome, and its automation level is relatively low. The crushing efficiency is not as high as that of hydraulic cone crushers.

Applications: It is suitable for medium and fine crushing of various ores and rocks in metallurgy, building materials, chemical and other industries, especially for materials with medium hardness.

Single-cylinder Hydraulic Cone Crusher

Working Principle: The hydraulic cylinder is used to adjust the discharge port and provide overload protection. The main shaft of the crusher is driven by an eccentric sleeve to make a gyratory motion, and the material is crushed between the movable cone and the fixed cone.

Advantages: It has a simple structure, low manufacturing cost and stable performance. It is easy to realize automatic control. The product has a uniform particle size and less needle-like material.

Disadvantages: The crushing force is slightly insufficient, especially for hard materials. Uneven feeding can cause uneven wear of the rolling wall. The lower working space is small, which makes maintenance difficult.

Applications: It is suitable for medium hardness crushing, fine crushing and even ultra-fine crushing. It is widely used in mining, building materials, highway and other industries.

Multi-cylinder Hydraulic Cone Crusher

Working Principle: Multiple hydraulic cylinders are used to lock and adjust the crushing cavity. The main shaft is in the form of a cantilever beam support and a spherical tile support structure. The high swing frequency and large eccentricity improve the crushing efficiency.

Advantages: It has a large crushing force and is suitable for crushing hard materials. The discharge adjusting range is wide, and it is more flexible in adjusting the product grade.

Disadvantages: The small spherical radius and swing radius may cause unstable phenomena such as the movable cone swaying and overturning, affecting the normal operation of the machine.

Applications: It is mainly used for crushing hard ores and rocks in metal mines, quarries and other places, and is suitable for fine crushing and ultra-fine crushing operations.

Symons Cone Crusher

Working Principle: It uses a combination of springs and hydraulic cylinders to adjust the discharge opening. The movable cone rotates around the fixed axis under the action of the eccentric sleeve, and the material is continuously crushed by the extrusion and impact between the movable cone and the fixed cone.

Advantages: It is durable, reliable and has high crushing efficiency. It can control the particle size of the product by adjusting the discharge port.

Disadvantages: Compared with the hydraulic cone crusher, its structure is heavier, and the crushing force and production capacity are relatively small.

Applications: It is used as a medium crusher or fine crusher in mines, quarries and construction sites where high granularity standards are not required.

Gyratory Cone Crusher

Working Principle:It consists of a fixed cone and a movable cone. The movable cone gyrates eccentrically within the fixed cone. As materials enter the crushing chamber, they are squeezed and crushed between the two cones. The gyrating motion of the movable cone continuously applies pressure to the materials, reducing them to smaller sizes.

Advantages: As a primary crushing machine, it can handle a large volume of materials, suitable for large-scale production. With a robust structure, it can operate continuously for a long time with high reliability.

Disadvantages: Gyratory cone crushers are large and bulky, requiring a large installation area and a solid foundation. It requires uniform and continuous feeding to the crushing effect and product quality. Gyratory cone crushers are not suitable for processing materials with too high moisture content. Maintenance requires professional technical personnel and specialized tools. And the cost is higher too.

Applications: It is widely widely used in the crushing of various metal and non-metal ores, such as iron ore, copper ore. Processes raw materials like granite, basalt for producing aggregates used in concrete and road construction.

Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Stone cone crusher is one of its core production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you want to get more information about cone crusher, please click on the online consultation to contact us. Baichy Machinery is dedicated to serving you 24 hours a day!

2025-04-13

2025-04-13

86-15093113821

86-15093113821

86-15093113821

86-15093113821