A concrete crusher is a specialized machine designed to break down concrete waste—such as demolished buildings, roads, bridges, or leftover construction materials—into smaller, reusable fragments (e.g., gravel, aggregates, or sand). These machines play a critical role in recycling construction and demolition (C&D) waste, reducing landfill reliance, and promoting sustainable construction practices.

Key Features of Concrete Crushers

Concrete crushers are engineered to handle the hardness and density of concrete, which often contains embedded materials like steel reinforcement bars (rebar), rocks, or bricks. Their core features include:

-High crushing force: To break through tough concrete matrices.

-Durable components: Wear-resistant jaws, hammers, or cones (depending on the type) to withstand abrasion.

-Adjustable output size: Allowing operators to produce aggregates of specific dimensions (e.g., 20mm, 40mm) for reuse in new construction, road base, or backfill.

Types of Concrete Crushers

Different crusher designs are used based on the volume of waste, desired output size, and presence of contaminants (like rebar). Common types include:

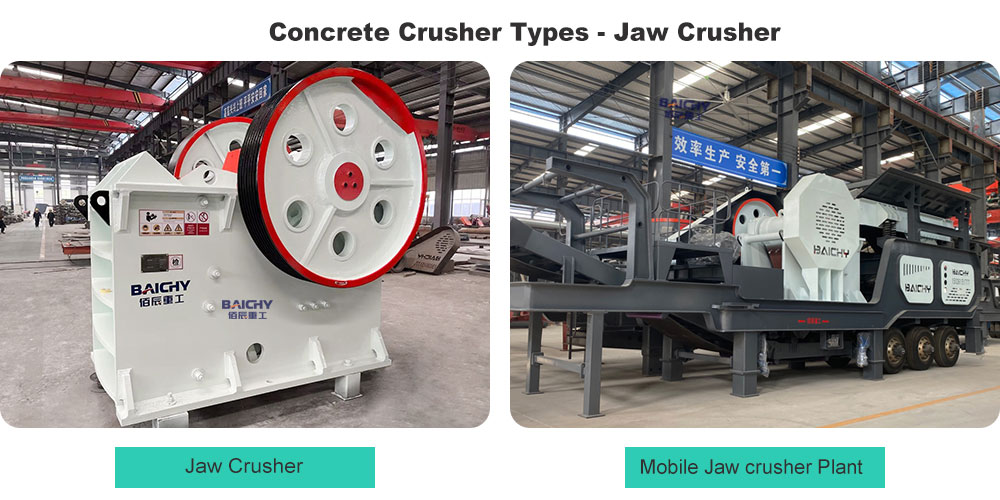

1.Jaw Crushers

Jaw crushers are well - suited for the initial stage of crushing concrete waste. They have a simple yet robust design, with a fixed jaw and a movable jaw. The movable jaw reciprocates against the fixed jaw to crush the concrete waste. They can handle large chunks of concrete waste that are often produced indemolition sites. Their ability to handle large feed sizes makes them a good choice for the first step in the crushing process. So about jaw crusher, we know:

-How they work: Use a fixed "jaw" and a moving jaw that compresses concrete between them, applying pressure to break it apart.

-Best for: Primary crushing of large concrete chunks (e.g., demolished walls or slabs) into smaller pieces (typically 50–200mm).

-Note: Effective for coarse crushing but may not remove rebar; additional sorting is often needed.

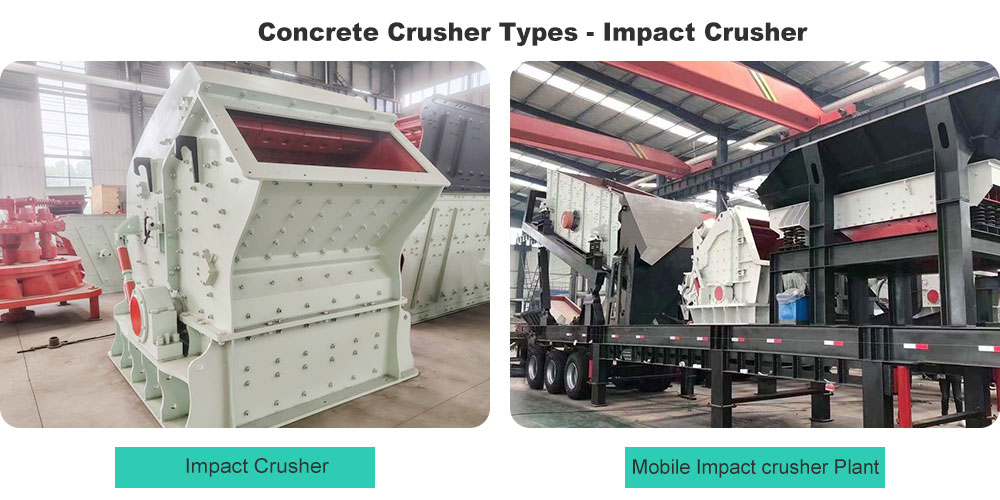

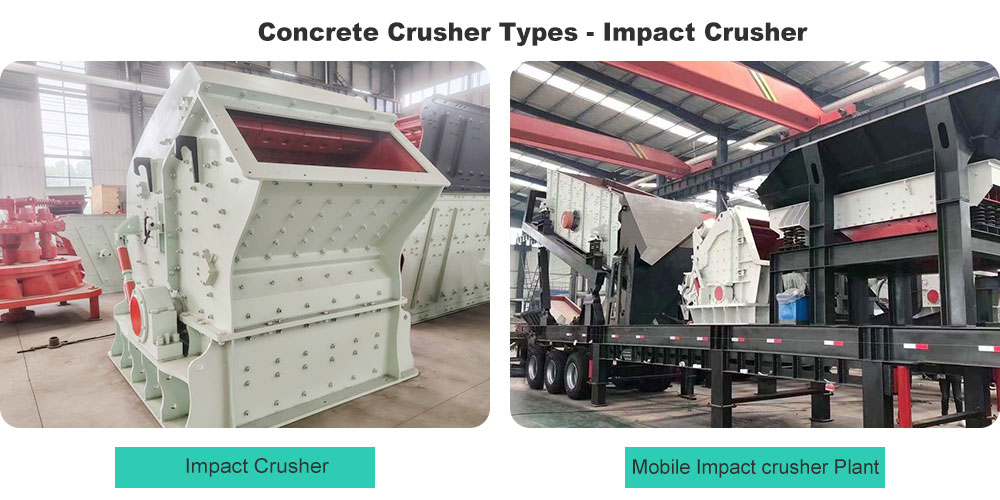

2.Impact Crushers

Impact crushers are excellent for concrete waste recycling. They work by using a high - speed rotor with hammers or blow bars. When concrete waste is fed into the crusher, the hammers strike the material, breaking it into smaller pieces. The impact action is very effective for crushing concrete waste because it can handle a variety of shapes and sizes of waste concrete, including pieces with rebar (though rebar can cause more wear and tear). Impact crusher produce a more cubical - shaped product, which is highly desirable for recycled concrete aggregate. So about impact crusher to crush concrete , we know below:

-How they work: Utilize high-speed rotating hammers or blow bars to strike concrete, shattering it through impact force.

-Best for: Secondary crushing to produce finer aggregates (e.g., 10–50mm). They can also separate rebar from concrete as the material breaks apart, making them ideal for recycling.

-Subtypes: Horizontal shaft impactors (HSI) and vertical shaft impactors (VSI), with VSIs producing more uniform, cubical aggregates.

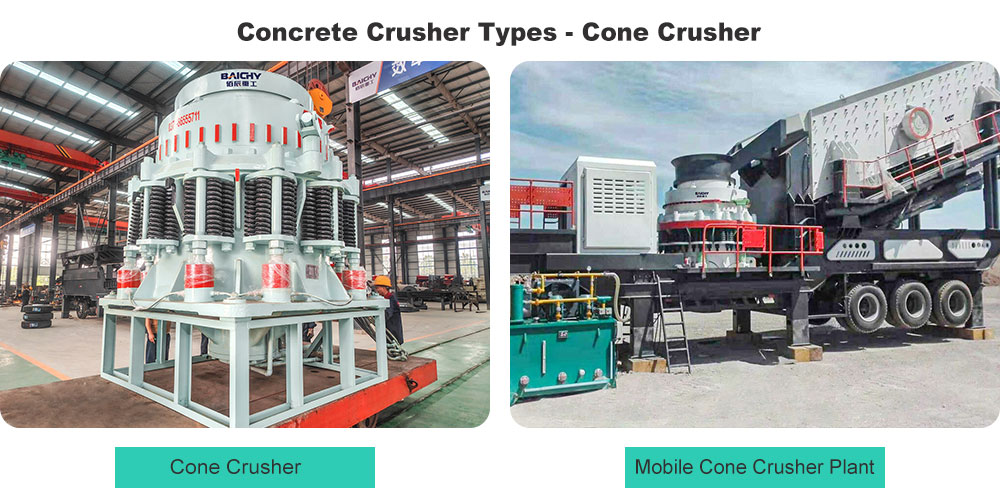

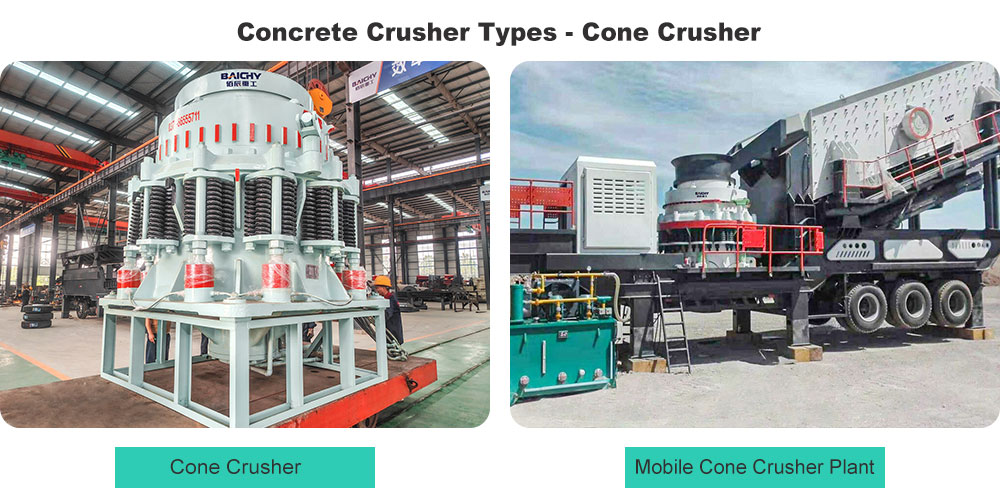

3.Cone Crushers

Cone crushers are powerful machines commonly used in the construction and mining industries to crush various types of materials, including concrete, into smaller, more manageable sizes. They are especially effective for secondary and tertiary crushing stages, where the material has already been pre-crushed. Cone crushers operate by squeezing the material between an eccentrically rotating mantle and a concave hopper. As the mantle moves, it crushes the concrete against the concave surface, breaking it down into smaller aggregates. So about impact crusher to crush concrete , we know below:

-How they work: Use a rotating cone that gyrates within a fixed concave chamber, crushing concrete through compression and friction.

-Best for: Hardened or high-strength concrete, producing consistent, medium-to-fine aggregates (e.g., 5–40mm). They are often used after jaw crushers in multi-stage crushing processes.

-Design: Mounted on tracks or wheels for on-site mobility, allowing crushing directly at demolition sites.

-Advantage: Eliminates the need to transport heavy concrete waste to a fixed facility, reducing logistics costs and carbon emissions. They may combine jaw, impact, or cone crushing mechanisms in one unit.

How Concrete Crushers Work: A Basic Process

1.Feeding: Concrete waste is loaded into the crusher (via conveyors, skips, or excavators).

2.Crushing: The machine applies force (compression, impact, or friction) to break the concrete into smaller pieces.

3.Screening: Crushed material is often passed through a screen to separate oversized particles, which are recirculated for further crushing.

4.Separation: Steel rebar or other contaminants are removed using magnets (for ferrous metals) or manual sorting.

5.Output: The resulting aggregates are stored or transported for reuse in new concrete, road construction, or landscaping.

Applications of Crushed Concrete

-Recycled aggregates: Used as a substitute for natural gravel in concrete mixes, road bases, or fill material.

-Landscaping: As drainage material or decorative stone.

-Backfill: For foundations, trenches, or utility projects.

By converting waste concrete into reusable materials, concrete crushers contribute to a circular economy, reducing the need for virgin aggregates and lowering the environmental impact of construction activities.

Baichy Machinery has a history of more than 20 years. It not only produces a full set of crushing and sand making equipment, but also provides EPC project general contracting services, including plant site selection and construction, production line design and installation, and production and operation technical training. Welcome to consult online to get your exclusive conrete crushing and recycling plant solution.

People Also Frequently Asked For - FAQ

1.What is crushed concrete used for?

Crushed concrete is a versatile and cost-effective material used in a variety of construction and landscaping applications. It's commonly used as a base for roadways, driveways, and parking lots, as well as for drainage and erosion control in landscaping projects. Its durability and ability to improve drainage make it a practical choice for many projects.

2.What is the best way to crush concrete?

You will want to crush larger pieces of concrete into more manageable pieces using a compact and mobile jaw crusher. If the job requires a bigger machine, jaw crushers come in a full range of sizes; check out different crushers here.

3.What type of crusher is best for concrete?

Jaw crushers are good for crushing big chunks of concrete, while cone crushers are better for crushing concrete into finer particles. Impact crushers can handle both big and small pieces of concrete, making them a versatile option in a variety of different types of projects.

4.Is crushing concrete profitable?

Yes, concrete crushing can be highly profitable. By recycling concrete and other demolition materials into valuable aggregate, businesses can save on disposal fees, produce a sellable product and capitalize on increasing demand for sustainable construction practices.

2025-11-22

2025-11-22

86-15093113821

86-15093113821

86-15093113821

86-15093113821